Configuration Via the Mains: Simple, Reliable and Professional

As the heart of any LED luminaire, the LED driver not only has to meet strict requirements in terms of quality and reliability but also be flexible enough to adapt to different conditions. ready2mains – a new technology from Tridonic – helps enormously. The article explains what is needed and how it works.

The most important parameter for any LED driver is the output current. This determines the operating point of the connected LED module, its operating temperature and therefore the lifetime of the luminaire. Whereas intelligent devices with separate communication interfaces such as DALI and DSI have long been able to automatically set the output current with a high degree of flexibility, devices without such an interface have had to go without this useful feature. The inconvenience of dealing with resistance plugs or setting DIP switches made it difficult to integrate these devices in partially or fully automated production lines. The current always had to be manually configured.

For the first time, ready2mains technology enables drivers with manually adjustable output current (often known simply as fixed-output drivers) to be automatically configured, offering maximum flexibility in the rapidly expanding segment of LED lighting. At the heart of this new technology is the ready2mains programmer – a programming unit that enables configuration data to be digitally modulated on the mains cable (Figure 1). It is simply connected as a digital communications interface between the mains cable and the driver, providing a quick and easy way to automate configuration.

Digital data transfer also for fixed-output drivers

ready2mains enables not only LED drivers with separate communications interfaces but also drivers with manually adjustable output current to be programmed quickly, automatically and with a high degree of flexibility. The configuration parameters are transferred via the existing mains cable. This involves modulating the parameters on the mains cable in digital form via the ready2mains programmer. The parameters can be selected either directly on the programmer or in appropriate configuration software. If configuration software is used, additional parameters such as the Constant Light Output function can be set, provided the driver supports this function. Successful programming is signalled both by the luminaire itself and by the configuration software.

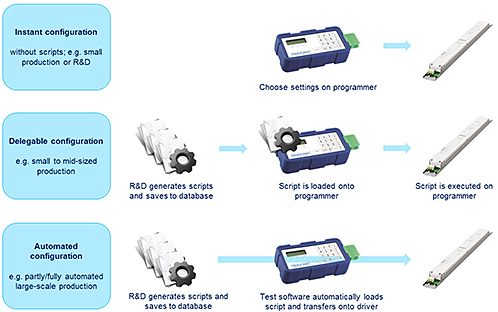

The benefits compared with conventional manual current setting methods are huge. Transmission of the data in digital form is quick and less susceptible to error thanks to the lack of manual steps. It can also be easily integrated in automated processes (Figure 2). The cost aspect is another benefit of this interface implementation, as a DC recognition function is already integrated in the LED drivers. By making use of this function, ready2mains can be implemented without any additional costs for the products. Obviously, it is still possible to set the current manually via resistance plugs.

Figure 2: The typical applications of the new technology can be flexibly combined, if necessary

Figure 2: The typical applications of the new technology can be flexibly combined, if necessary

Simplified workflows

Luminaire-specific parameter sets can be created, stored and reused in the form of scripts. This provides clear separation in terms of time and personnel between the creation of parameters and their transfer to the relevant drivers. If, for example, the development department of a luminaire manufacturer creates different scripts and verifies them, they will be available on a drive, clearly identifiable and tested. For the production process, these scripts can then be copied to the ready2mains programmer as part of the preparations. There is therefore no longer any need for a PC at the assembly and testing station on a production line. At the same time, there is a guarantee that incorrect parameters will not be used. It is possible to configure the drivers either before the luminaire is assembled or later in the completed luminaire. Throughput times can also be reduced because up to five drivers can be configured simultaneously.

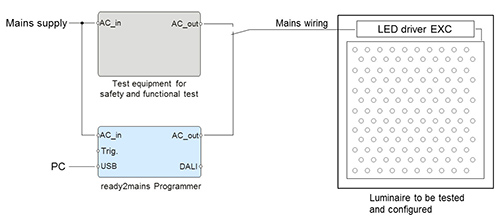

A software module specially developed for ready2mains also enables the driver configuration to be easily integrated in existing software-controlled test systems. During the safety and function tests the luminaires are connected to the mains anyway, and the programmer is simply connected between the luminaire and the mains. There is therefore no longer any need to configure the drivers manually before the test. To configure the luminaires, for example, the appropriate configuration scripts can be retrieved automatically from the database and transferred to the driver (Figure 3). The programmer receives the parameters to be configured via a USB interface, buffers them if necessary, and forwards them to the LED driver. To preclude later manipulation during operation a lock command can be set during configuration. This ensures that current programming can no longer be changed via the mains cable.

Figure 3: ready2mains can be easily integrated in existing testing processes

Figure 3: ready2mains can be easily integrated in existing testing processes

Electrical contractors also benefit

Luminaire manufacturers are not the only ones to welcome the new communications interface. Electrical contractors also benefit because on-site configuration whenever complete luminaires or individual components are replaced is now much easier. They do not have to manually configure the driver and do not have to keep a stock of resistance plugs.

Focus on data transfer

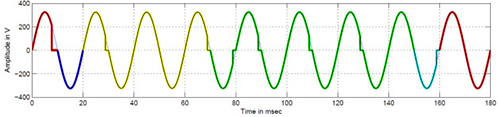

ready2mains transfers all the information in digital form. A self-contained data block is referred to here as a frame. This comprises a total of 18 half-waves, each representing a digital value. Presence of a trailing edge corresponds to a value of "1" or "TRUE"; absence of a trailing edge corresponds to "0" or "FALSE". A frame is subdivided into individual elements and contains partial information such as the start and end points of the frame or the value of a particular parameter (Figure 4). For data transfer, the frames are modulated by the programmer on the mains cable. The driver decodes the transferred signals to obtain the parameter values and information on their validity.

Figure 4: Basic structure of a frame - red indicates the start and end bits, blue the frame type, yellow the function, green the configuration data, and turquoise the parity bit

Figure 4: Basic structure of a frame - red indicates the start and end bits, blue the frame type, yellow the function, green the configuration data, and turquoise the parity bit

To ensure correct data transfer, several checks are used simultaneously. The parity check works with a special error bit which detects the "flipping" of a bit during transfer. There is also a checksum calculation in which the different values of a frame are mathematically checked against one another. The result is also transferred to the driver, enabling it to check the data for correctness. If the driver finds a discrepancy it will ignore this frame and immediately switch off. This disconnection is detected by the programmer and signalled accordingly.

Only if both tests are successfully completed will a third test, namely power measurement through load modulation, be automatically performed. This involves the driver changing the current through the connected LED module in a predefined sequence. Evaluation of the measured power ensures that the data has been correctly received and stored. This visual feedback and an appropriate message at the programmer and via the USB interface indicate successful completion of data transfer. The different tests ensure correct configuration with ready2mains. In addition, use of the phase angle (= the duration of the trailing edge) increases fault tolerance and improves immunity.

Summary

ready2mains is the modern way to configure LED drivers and does not require an additional interface. For the first time, configuration via the mains cable allows drivers without a separate communications interface (fixed-output drivers) to be digitally configured. The new interface therefore offers a future-proof alternative to existing methods and is far superior in terms of fault tolerance, safety and flexibility. The only requirement is that the drivers must be compatible with ready2mains. This is true of the Premium (PRE) and Excite (EXC) product families and various outdoor devices from Tridonic.