High output light emitting diode and method for fabricating the same

A high output light emitting diode (LED) and a method for fabricating the LED is disclosed. The LED includes a sidewall or surface that is inclined. A reflective film is formed on the inclined sidewall or surface to allow light to reflect from the reflective film and to emit the light upward or in a favorable direction with respect to the device, thereby being configured and enabled to improve a light output of the LED and dispense with an additional passivation process.

Background of the invention

Field of the Invention

[0002] The present invention relates to a high output light emitting diode (LED) and a method for fabricating the same wherein a sidewall of the LED is inclined and a reflective film is formed on the inclined sidewall to allow light emitted outside of the sidewall to reflect from the reflective film and to emit upward of the device, thereby enabling to improve a light output and dispensing with an additional passivation process.

Discussion of the Related Art

[0003] Generally, an LED is widely used in applied fields such as color bulletin boards, traffic lights, keypad light sources for mobile telephones, light sources for illumination and LCD backlights.

[0004] FIG.1 is a cross-sectional view of a conventional LED. The LED includes a substrate (10) sequentially stacked thereon with an N-type semiconductor layer (11), an active layer (12) and a P-type semiconductor layer (13), mesa etched from the P-type semiconductor layer (13) to portions of the N-type semiconductor layer (11), a transparent electrode (14) formed on the P-type semiconductor layer (13), an N electrode (15) formed on the mesa-etched N-type semiconductor layer (11) and a P electrode (16) formed on the transparent electrode (14).

[0005] If current flows in the N electrode (15) and the P electrode (16) in the LED, light is generated from the active layer (12) and emitted outside of the device. Many attempts have been made to increase the light output of the LED, and a device manufacturing of flip chip structure is one of the attempts.

[0006] FIG.2 is a mimetic cross-sectional view of a flip chip LED bonded to a sub mount substrate according to the prior art. Referring to the LED structure of FIG.1, the flip chip LED is structured in such a manner that the P-type semiconductor layer (13) is stacked thereon with a reflective film (16) for P electrode, the reflective film (16) and the N electrode (15) are bonded to a sub mount substrate (30) by conductive bonding materials such as solders (20a. 20b), and light is emitted toward the substrate (10).

[0007] In other words, the flip chip type light device is such that the light emitted from the active layer (12) is reflected from the reflective film (16) to be emitted outside of the device via the substrate (10).

[0008] However, the light emitted from the flip chip type light device is reflected from an entire surface of the device to the disadvantage of wasting the light emitted from the sidewall of the device.

[0009] Particularly, in the case of a cleavage plane of the device, part of light emitted from a sidewall of the device is reflected from the cleavage plane, confined inside the device and cannot be emitted therefrom, thereby resulting in decreased light emission from the device.

Brief summary of the invention

[0010] The present invention is directed to solve the afore-mentioned problems, and it is an object of the invention to provide a high output LED and a method for fabricating the same wherein a sidewall of the LED is inclined and a reflective film is formed on the inclined sidewall to allow light emitted outside of the sidewall to reflect from the reflective film and to emit upward of the device, thereby enabling to improve a light output and dispensing with an additional passivation process.

[0011] Another object of the invention is to form a curvature on a sidewall of a light emitting structure to increase a light emitting area and to improve a light output.

[0012] Still another object is to create a cylindrical LED and to uniformly pass current, thereby enabling light emitted from a light emitting surface to be outputted in a uniform strength.

[0013] In a first aspect of the invention, a high output LED comprising a structure sequentially stacked with an N-type semiconductor layer, an active layer and a P-type semiconductor layer to allow the light emitted from the active layer, is formed in such a manner that a front surface of a sidewall of the structure stacked with the N-type semiconductor layer, the active layer and the P-type semiconductor layer is inclined, and a reflective film is formed at an entire inclined sidewall for reflecting light emitted from the active layer.

[0014] In a second aspect of the invention, a high output LED is formed in such a manner that a substrate is sequentially stacked thereon with an N-type semiconductor layer, an active layer and a P-type semiconductor layer, mesa-etching is performed from the P-type semiconductor layer to portions of the N-type semiconductor layer, a mesa-etched sidewall and sidewalls of the P-type semiconductor layer, the active layer and N-type semiconductor layer are all inclined, the inclined sidewalls are formed with a reflective film, an N electrode is formed on the mesa-etched N-type semiconductor layer, and a P electrode is formed on the P-type semiconductor layer.

[0015] In a third aspect of the invention, a high output LED is formed in such a manner that an active layer and a N-type semiconductor layer are sequentially stacked on a P-type semiconductor layer, sidewalls of the P-type semiconductor layer, the active layer and the N-type semiconductor layer are inclined, the inclined sidewalls are formed with reflective films, and the N-type semiconductor layer is formed thereon with an N electrode.

[0016] In a fourth aspect of the invention, a method for fabricating a high output LED comprising: sequentially stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate; mesa-etching in such a manner that mesa-etched sidewalls from the P-type semiconductor layer to portions of the N-type semiconductor layer are inclined; etching the remaining sidewalls of the N-type semiconductor, the active layer and the P-type semiconductor layer except for the mesa-etched portions to form inclined sidewalls; evaporating reflective films on the inclined sidewalls; and forming an N electrode on the mesa-etched N-type semiconductor layer, and forming a P electrode on the P-type semiconductor layer.

[0017] In a fifth aspect of the invention, a method for fabricating a high output LED comprising: sequentially stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate; etching from the P-type semiconductor layer to portions of the N-type semiconductor layer and forming an inclination on the etched sidewalls; detaching the substrate from the N-type semiconductor layer; forming a reflecting P electrode underneath the P-type semiconductor layer; and forming a reflective film on the inclined sidewalls and forming an N electrode on the N-type semiconductor layer.

[0018] In a sixth aspect of the invention, a method for fabricating a high output LED comprising: sequentially stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate; forming a mask layer formed with a curvature on a sidewall on an upper surface of the P-type semiconductor layer; masking the P-type semiconductor by the masking layer and etching from the P-type semiconductor layer to the N-type semiconductor layer to form an inclination and indents on the etched sidewalls; detaching the substrate from the N-type semiconductor layer; forming a reflecting P electrode underneath the P-type semiconductor layer; and forming a reflective film on the inclined sidewalls; and forming an N electrode on the N-type semiconductor layer.

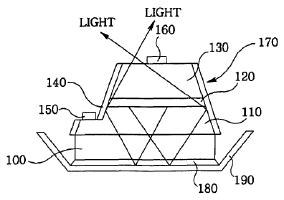

[0019] In a seventh aspect of the invention, a method for fabricating a high output LED comprising: sequentially stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate; forming on the P-type semiconductor layer a plurality of disc-shaped mask layers, each mask layer spaced a predetermined distance apart; masking the P-type semiconductor layer by the plurality of mask layers and etching from the P-type semiconductor layer to the N-type semiconductor layer to form an inclination on the etched sidewalls; detaching the substrate from the N-type semiconductor layer to obtain a plurality of light emitting structures on which a P-type semiconductor layer, an active layer and an N-type semiconductor layer are stacked; forming reflective films on each sidewall of the light emitting structures; forming N electrodes underneath each N-type semiconductor layer of the light emitting structures; and forming P electrodes on each P-type semiconductor layer of the light emitting structures.

Claims

1. A high output light emitting diode (LED) comprising:

a structure having an inclined surface that includes an N-type semiconductor layer, an active layer and a P-type semiconductor layer; and

a reflective film disposed along substantially all of the inclined surface to reflect light emitted from the active layer;wherein the N-type semiconductor layer, the active layer, and the P-type semiconductor layer are provided in a stack, said stack being configured to allow light to be emitted from the active layer.

2. The LED as defined in claim 1, further comprising an angle defined by the inclined sidewall, the angle being in a range of 30~70 degrees.

3. The LED as defined in claim 1, wherein the reflective film comprises an anti-reflection (AR) film, a film stacked with reflective layers, or a high-reflection (HR) film.

4. A high output light emitting diode (LED) comprising:

a stack including an N-type semiconductor layer, an active layer, and a P-type semiconductor layer, said stack including mesa-etched sidewalls from the P-type semiconductor layer to portions of the N-type semiconductor layer, wherein the mesa-etched sidewalls and sidewalls of the active layer are inclined;

a reflective film disposed along the inclined sidewalls;

an N electrode being disposed on the N-type semiconductor layer,

a P electrode being disposed on the P-type semiconductor layer; and

a substrate attached to the stack.

5. The LED as defined in claim 4, wherein the inclined sidewalls comprise indents.

6. A high output LED comprises:

a structure including an active layer, an N-type semiconductor layer, and a P-type semiconductor layer, wherein the P-type semiconductor layer, the active layer and the N-type semiconductor layer include inclined sidewalls;

reflective films being disposed along the inclined sidewalls; and

an N electrode being disposed on the N-type semiconductor layer.

7. The LED as defined in claim 6, wherein the inclined sidewalls comprise indents.

8. The LED as defined in claim 7, wherein the indents comprise planar portions and curved portions.

9. The LED as defined in claim 6, wherein the P-type semiconductor layer, the active layer and the N-type semiconductor layer are configured in a stack such that a diameter of the P-type semiconductor layer is smaller than a diameter of the N-type semiconductor layer.

10. A method for fabricating a high output LED comprising:

stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate;

mesa-etching sidewalls to be inclined from the P-type semiconductor layer to portions of the N-type semiconductor layer;

etching remaining sidewalls of the N-type semiconductor, the active layer, and the P-type semiconductor layer except for the mesa-etched sidewalls to be inclined; evaporating reflective films on the inclined sidewalls; and

forming an N electrode on the mesa-etched N-type semiconductor layer, and forming a P electrode on the P-type semiconductor layer.

11. The method as defined in claim 10, wherein an inclination of the inclined sidewalls is in a range of 30~70 degrees.

12. The method as defined in claim 10, wherein the reflective film is an ant-reflection (AR) film, a film stacked with reflective layers, or a high-reflection (HR) film.

13. A method for fabricating a high output LED comprising:

stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate;

etching sidewalls from the P-type semiconductor layer to portions of the N-type semiconductor layer;

forming an inclination on the etched sidewalls;

detaching the substrate from the N-type semiconductor layer;

forming a reflecting P electrode under the P-type semiconductor layer; and

forming a reflective film on the inclined sidewalls and forming an N electrode on the N-type semiconductor layer.

14. The method as defined in claim 13, wherein the inclination is in a range of 30 70 degrees.

15. The method as defined in claim 13, wherein the reflective film is an anti-reflection (AR) film, a film stacked with reflective layers, or a high-reflection (HR) film.

16. A method for fabricating a high output LED comprising:

stacking an N-type semiconductor layer, an active layer and a P-type semiconductor layer on a substrate;

forming a mask layer with a curvature on a sidewall of an upper surface of the P-type semiconductor layer;

masking the P-type semiconductor with the mask layer and etching from the P-type semiconductor layer to the N-type semiconductor layer to create inclinations and indents on sidewalls of the stack;

detaching the substrate from the N-type semiconductor layer;

forming a reflecting P electrode under the P-type semiconductor layer;

forming a reflective film on the inclined sidewalls; and

forming an N electrode on the N-type semiconductor layer.

17. The method as defined in claim 16, wherein the mask layer includes a marginal sidewall with indents comprising planar or curved portions.

18. A method for fabricating a high output LED comprising:

stacking an N-type semiconductor layer, an active layer, and a P-type semiconductor layer on a substrate;

forming a plurality of disc-shaped mask layers on the P-type semiconductor layer, each disc-shaped mask layer being spaced a predetermined distance apart;

masking the P-type semiconductor layer by the plurality of mask layers and etching from the P-type semiconductor layer to the N-type semiconductor layer to create an inclination on sidewalls of the stack;

detaching the substrate from the N-type semiconductor layer to obtain a plurality of light emitting structures that includes the P-type semiconductor layer, the active layer and the N-type semiconductor layer;

forming reflective films on side surfaces of the light emitting structures;

forming N electrodes adjacent to each N-type semiconductor layer of the light emitting structures; and

forming P electrodes adjacent to each P-type semiconductor layer of the light emitting structures.

19. The method as defined in claim 18, wherein the light emitting structure comprises a diameter of the P-type semiconductor layer that is smaller than a diameter of the N-type semiconductor layer.

See full document in pdf.