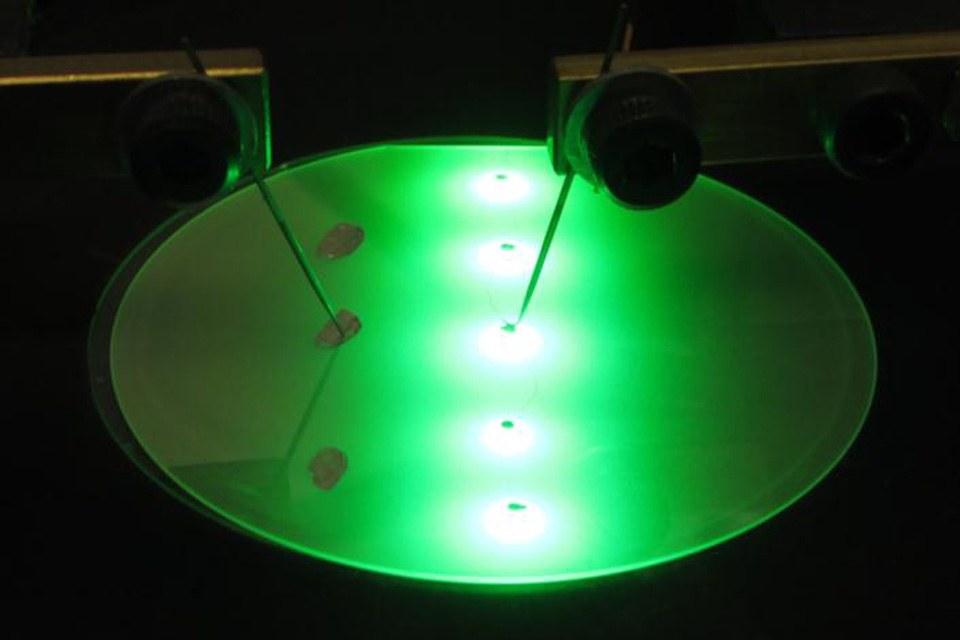

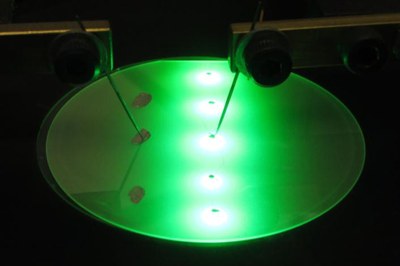

BluGlass Demonstrates Improved Performance Results for Green RPCVD Manufactured p-GaN LEDs

BluGlass has succeeded in its initial experimentation of applying low temperature RPCVD p-GaN to Green LED applications with highly promising results. These results show that the green LEDs produced using RPCVD p-GaN are demonstrating greater efficiency than the BluGlass grown MOCVD benchmark LEDs using the exact same MOCVD grown multi-quantum wells (MQWs), the critical light emitting region of an LED device.

| Electroluminescence Data (Wafer Quick Test)* | At 20 mA | At 50 mA |

| Light Output (mW) | 0.9 | 2.5 |

| Vf (V) | 3.5 | 4.5 |

| Peak Wavelength (nm) | 520 | 517 |

| Full Width at Half Maximum (nm) | 33 | 37 |

This indicates that the RPCVD process’ low temperature benefits are helping to improve green LED device performance through the reduced degradation of the temperature sensitive MQW layers. BluGlass will continue to conduct experimentation to further validate these results.

BluGlass’ Chief Operations and Technology Officer, Dr. Ian Mann said today “This is great early performance data, which we expect to continue to improve further; especially given that BluGlass has only recently attempted growing green MQWs using MOCVD. Our recent focus has been on optimising the quality of the RPCVD p-GaN overgrowth process. It is very encouraging that for the first time, in a side by side RPCVD p-GaN versus MOCVD p-GaN overgrowth experiment, to show that RPCVD has provided a performance edge in LED efficiency."

Dr. Mann added “The significant efforts in improving blue LEDs over the last 12 months has shown to be readily transferable to the efforts in green LEDs.”

At the Company’s AGM at the end of 2014, BluGlass outlined its intentions to expand the RPCVD research into new, high growth market applications with strong potential for a low temperature deposition technology such as power electronics, green and yellow LEDs and UV LEDs. The value of this action was recently reconfirmed by Veeco Instruments Inc, asking to evaluate the RPCVD p-GaN for both green LEDs and power electronic applications.

Green LEDs are important for RGB (Red, Green and Blue) LED applications that enable the device to have full colour control. The LED industry is very interested in the possibility of a cost effective RGB solution to create more natural looking light and is expected to be popular for segments of the general lighting market.

The value proposition for RPCVD for green LED applications is similar to that of high brightness blue LEDs. The low temperature process is expected to offer performance advantages; however the value proposition is even greater for the green LED market opportunity. This is because green LEDs require high indium content MQWs and therefore benefit from a lower temperature growth process. Low temperature growth enables both; less degradation of the MQW, and provides higher indium concentration (the core material required to create the green wavelength). While RPCVD grown green MQWs have not yet been demonstrated (the results presented to date are for MOCVD grown MQWs) we believe the combination of an all RPCVD grown MQW and p-GaN is compelling from a performance and cost perspective.

IP Update:

In addition BluGlass has recently had another core patent granted in the US and an additional two patents accepted in Europe and Australia.

About BluGlass:

BluGlass Limited (winner of the 2013 Australian Cleantech Competition) is an Australian green technology company formed to commercialise a breakthrough in the Semiconductor Industry. BluGlass has invented a new process using Remote Plasma Chemical Vapour Deposition (RPCVD) to grow semiconductor materials such as gallium nitride (GaN) and indium gallium nitride (InGaN), crucial to the production of high efficiency devices such as next generation lighting technology Light Emitting Diodes (LEDs) with advanced low cost potential.

The RPCVD technology, because of its low temperature and highly flexible nature, offers many potential benefits over existing technologies including higher efficiency, lower cost and greater scalability.