CTI Project Results Promise a Bright Future for OLEDs

Developing a low-cost, efficient method of increasing the attractiveness of OLEDs for lighting poses a significant challenge. Thanks to a CTI project, CSEM and Sefar AG have succeeded in designing a promising state-of-the-art way of achieving this aim. This technology opens up new opportunities for applications in residential, architectural, professional lighting segments, as well as consumer electronics.

OLEDs (Organic Light-Emitting Diodes) have long been deemed to be the lighting technology of the future. However, their market penetration remains minute due to their high production costs and moderate light output compared to, for example, inorganic LEDs.

Considerable resources have been applied, unsuccessfully, to overcoming these barriers. Thanks to a project supported by the Swiss Confederation (CTI project), CSEM and the company Sefar are now able to propose a promising solution featuring interesting production costs, high efficiency, and compatibility with the fabrication of large-area OLEDS.

Low-cost, flexible, highly transparent but still highly conductive:

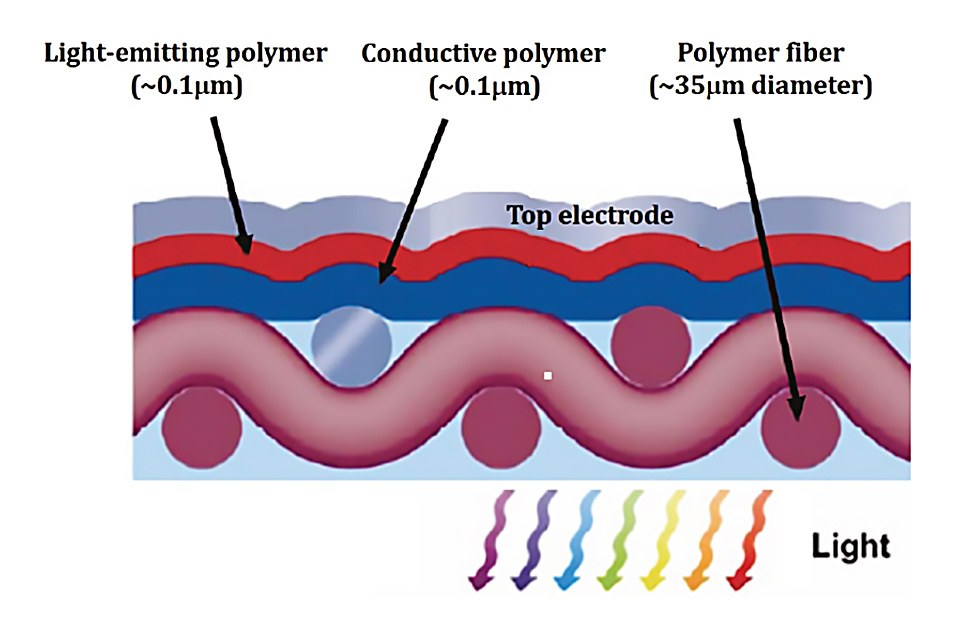

Together, the partners have developed low-cost, flexible, transparent, highly conductive electrodes made of fabric substrates comprising flexible metallic wires and polymeric fibers woven together in a highly transparent and flexible polymer. These fabric substrates (SEFAR® TCS Planar) are manufactured using low-cost, high-throughput processes under standard ambient clean room conditions.

The OLEDs are finalized by coating the substrate with a thin-film (tens of nanometers) layer of a solution-process conductive polymer. The high electrical conductivity of the metal wires in the fabric substrate ensures that the electrode displays high conductivity over large distances, even with an ultra-thin, and hence highly transparent, layer of the conductive polymer.

“The wet deposition of the different ultra-thin OLED layers with excellent thickness uniformity and minimum leakage current was the main challenge faced by CSEM,” explains Rolando Ferrini, Head of CSEM’s Integrated Light Management Section.

Real, far-reaching potential for optoelectronic devices:

“The use of Sefar fabric-based electrodes significantly simplifies the production of large-area OLEDs by eliminating the evaporation, photolithography, and electrical insulation of the supporting metal tracks,” continues Peter Chabrecek, R&D manager at Sefar. “With this achievement, our company aspires to reach 20 percent of the flexible transparent electrodes market by 2020 for all types of optoelectronic devices.” The groundbreaking solution can be applied for OLEDs, as well as for many other products, including solar cells, EL devices, touch screens, electrochromic glasses, transparent heating elements, sensors, photo-detectors, and transparent shielding elements.

CSEM will present the project at the LED Forum 2017 in Lausanne, on 25 January.

About CSEM:

CSEM, founded in 1984, is a Swiss research and development center (public-private partnership) specializing in microtechnology, nanotechnology, microelectronics, system engineering, photovoltaics and communications technologies. Around 450 highly qualified specialists.

Further information is available at www.csem.ch

About Sefar AG:

Sefar is the leading manufacturer of precision fabrics from monofilaments for the screen printing and filtration markets. Sefar products are used in a wide variety of industries, reaching from electronics, graphics, medical, automotive, food and pharma-ceutical applications to aerospace, mining and refining, and architecture. With its profound understanding of the applications, Sefar helps its customers to achieve optimum results in their industrial processes.

Subsidiaries and fabrication centers in 26 countries and on six continents provide local technical services for the broad range of solutions offered by Sefar. Sefar Group operates weaving plants in Switzerland, Romania, and Thailand. Its Monosuisse division produces fine and medium yarns in Switzerland, Poland, Romania, and Mexico.

In 2015 the Sefar Group achieved sales of 282 million Swiss Francs and employed some 2,200 employees.

Further information is available at www.sefar.ch