Light in New Shape - BMBF-Funded Joint Project R2D2

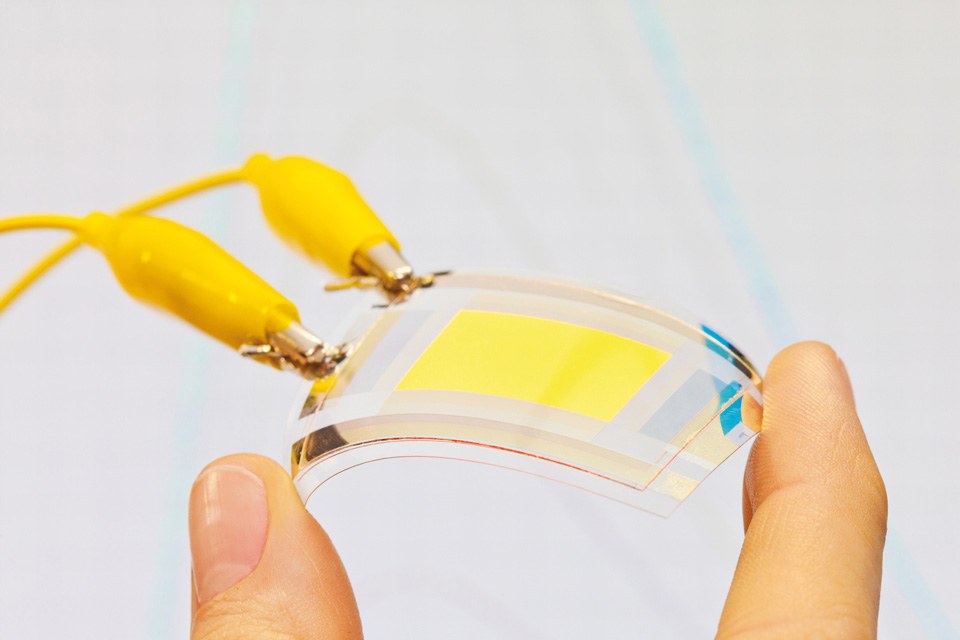

The research progresses of the last five years have proven the technical feasibility of the vision of a transparent and flexible light sources with very low energy consumption in the form of first demonstrators. Now the BMBF-funded joint project R2D2 will start in November 2014 aiming at the investigation of production-related processes and technologies for the manufacturing of flexible OLED.

The organic light-emitting diode, in short OLED, is characterized by specific features, which distinguishes it significantly from other light sources. The OLED is able to light up the entire area, whereas light bulbs, energy-saving lamps and classical LED are point light sources. It allows for transparent light sources with very low energy consumption, which furthermore can be applied to flexible and pliable substrates. The innovative world of light and design possibilities related to this progress had an important influence on the efforts for the development of OLED lighting technologies worldwide.

In the meantime leading lighting manufacturers have established pilot fabrication capacities for lighting-OLED on rigid glass substrates, e. g. the consortium partner OSRAM OLED. A significant penetration of the general lighting market can only be achieved if on the one hand the hitherto high production costs for OLED lamps can be reduced and on the other hand new fields of application and design can be opened up, which could not be served so far. The combination of the specific design characteristics planarity and flexibility with cost-effective manufacturing techniques provides an even economically promising alternative to the established lighting technologies.

“The BMBF-funded project R2D2 investigates production-related processes and technologies for the manufacturing of flexible and shapeable OLED. The piecewise manufacturing as well as the roll-to-roll technology approaches will be pursued.” says the consortium leader Dr. Christian May from Fraunhofer FEP. “The advantages and disadvantages of these manufacturing concepts as well as possible synergies shall be identified. Current challenges of the OLED, like durability, efficiency and homogeneity of the luminance will be addressed at the same time.”

The system integration of the manufactured flexible OLED modules for the use in automobiles, aircrafts and household applications is one of the main subjects of investigation within R2D2. According to the demands of these application fields durable, highly efficient materials, assembly and connecting technologies adapted for each application as well as system integration technologies will be researched and investigated. With the participation of Novaled a worldwide leading expert for OLED materials and technologies is member of the consortium. Moreover the consortium will be supported by VON ARDENNE GmbH, which is one of the market leaders for equipment for the highly productive roll-to-roll coating of flexible substrates and thus ensures the industrial feasibility of the developed technologies. Application and product studies including a detailed analysis of the manufacturing costs will be compiled.

The consortium would like to thank the BMBF for the project funding, which provides a subsidy of EUR 5.9 million over a period of 2 years.

R2D2 consortium:

The project consortium covers the entire value chain between material research, plant construction, component technology and application studies for future products. The planned activities are based on the worldwide recognized results of the BMBF-funded projects R2Flex, So-Light and TOPAS2012 for the organic electronics (especially organic light-emitting diodes and organic photovoltaics).

The direct participation of major lighting manufacturers (OSRAM OLED GmbH) and end users of the light sources (AUDI AG, Hella KGaA Hueck & Co and Diehl Stiftung & Co. KG) allows for a fast and comprehensive utilization of the project results, which affects the entire value chain by new possibilities of market penetration. R2D2 helps the organic light-emitting diode to gain a higher degree of reputation in the general public for the use in lighting applications and leads to a technological progress, which gives an economically important competitive advantage to German companies.

About Fraunhofer FEP:

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP works on innovative solutions in the fields of vacuum coating, surface treatment and processing with electrons and plasmas as well as organic semiconductors. The core competences electron-beam technology, sputtering and plasma-activated as well as PECVD high-rate coating, technologies for the organic electronic and IC/system design provide the basis for these activities. Thus Fraunhofer FEP offers a wide range of possibilities for research, development and pilot fabrication, especially for the processing, sterilization, structuring and refining of surfaces as well as OLED microdisplays, organic and inorganic sensors, optical filters and flexible OLED lighting. Our aim is to develop the innovation potential of the electron beam, plasma technology and organic electronic for new production processes and devices and to make it available for our customers.

About OSRAM OLED GmbH:

OSRAM OLED GmbH is a key innovator in the field of organic light emitting diode (OLED) technology. Research and development work is dating back to the beginnings of OLED research for display technologies in predecessor departments at the mother company OSRAM Opto Semiconductors GmbH. In more than 15 years a comprehensive knowledge and expertise in designing and processing of OLED devices was generated. OSRAM OLED is actively expanding this knowledge which makes the company a highly recognized partner in technology cooperations and customer projects.

By running a pilot production line in top-in-class cleanroom facilities at Regensburg, Germany, OSRAM OLED does not only emphasize laboratory achievements, but sets also a focus on production capable processes and reliability. OSRAM OLED is dedicated to high quality and has a clear mission to develop OLEDs for the use in automotive and general lighting applications.

Cutting edge technology and customer orientation are the basis for high level professional support and make OSRAM OLED a key player in the OLED landscape today.

About Novaled:

Novaled GmbH is a leader in the research, development and commercialization of technologies and materials that enhance the performance of OLEDs (organic light-emitting diodes) and other organic electronics. Novaled offers OLED product manufacturers a unique combination of proprietary technology, materials and expertise, and is currently the only company in the OLED industry licensing and selling organic conductivity doping technology and materials for use in the commercial mass production of display products. Novaled has developed strategic partnerships with key OLED innovators and producers throughout the world and, with a broad portfolio of more than 500 patents granted or pending, has a strong IP position in OLED technologies, structures and materials. Novaled is headquartered in Dresden with some 140 employees and offices in Asia.

For more information, please visit www.novaled.com.

About VON ARDENNE:

VON ARDENNE develops and manufactures advanced vacuum coating equipment for the deposition of nanometer to micrometer thin functional layers on materials such as glass, metal strip, wafers and polymer films. These materials are the basis for products such as architectural glass, solar modules, touch screens or heat protection films for automotive glass. VON ARDENNE is the market leader in manufacturing of architectural glass coating equipment. Beyond that, VON ARDENNE offers special systems for research and development purposes and does research in the fields of emerging technologies such as OLEDs on flexible substrates or transparent conductive oxides (TCO). The company holds 750 patents worldwide. It was founded as a spin-off of the Manfred von Ardenne Research Institute. The family owned company employs about 650 people and is based in Dresden. For more information, go to www.vonardenne.biz.

About Audi Group:

The Audi Group delivered approximately 1,575,500 cars of the Audi brand to customers in 2013. As one of the most successful models, the Audi A3 has been awarded the title of “World Car of the Year 2014“ by an international jury of journalists (combined fuel consumption in l/100 km: 7.1 – 3.2; combined CO2 emissions in g/km: 165 – 85). In 2013, the company reported revenue of €49.9 billion and an operating profit of €5.03 billion. The company operates globally in more than 100 markets and has production facilities in Ingolstadt and Neckarsulm (Germany), Győr (Hungary), Brussels (Belgium), Bratislava (Slovakia), Martorell (Spain), Kaluga (Russia), Aurangabad (India), Changchun (China) and Jakarta (Indonesia). Since the end of 2013, the brand with the Four Rings has also been producing cars in Foshan (China). In 2015, Audi will start production in São José dos Pinhais (Brazil), followed by San José Chiapa (Mexico) in 2016. Wholly owned subsidiaries of AUDI AG include quattro GmbH (Neckarsulm), Automobili Lamborghini S.p.A. (Sant’Agata Bolognese, Italy) and Ducati Motor Holding S.p.A. (Bologna, Italy), the sports motorcycle manufacturer. The company currently employs approximately 76,000 people worldwide, thereof more than 53,400 in Germany. Total investment of around €22 billion is planned from 2014 to 2018 – primarily in new products and sustainable technologies. Audi is committed to its corporate responsibility and has anchored the principle of sustainability for its products and processes in its strategy. The long-term goal is CO2-neutral mobility.

About Hella KGaA Hueck & Co:

HELLA is a global, independent family-owned company with more than 30,000 employees at 100 locations in more than 35 countries. The HELLA Group develops and manufactures lighting and electronic components and systems for the automotive industry, and also has one of the largest trade organizations for automotive parts, accessories, diagnosis and services within Europe. In the Special Applications segment, HELLA also develops products for specialist vehicles and entirely independent applications, such as street lighting or industrial lighting systems. Complete vehicle modules, air-conditioning systems and vehicle electrical systems are produced in joint venture companies. With more than 5,800 people working in research and development, HELLA is one of the most important innovation drivers on the market. In addition, with sales of around 5.3 billion euros in fiscal year 2013/2014, the HELLA Group is one of the top 50 automotive parts suppliers in the world and one of the 100 largest German industrial companies. www.hella.com

About Diehl Aerospace:

Diehl Aerospace is the leading German provider of avionics systems, cabin electronics and lighting designs for the international aviation industry. With strong core competencies in cockpits and cabins, Diehl Aerospace sets standards in state-of-the-art technology and customer service. The company is the global market leader in the area of cabin lighting for passenger aircraft and takes system responsibility in equipping the majority of the common platforms with cabin lighting. These include the Boeing 787 Dreamliner and the Airbus A350 XWB, whose cabins are the first to feature all-LED technology. Research and development is a key priority for the company. At its site in Nuernberg Diehl Aerospace operates the so-called Light Verification Center – the largest research facility for cabin lighting in Europe. www.diehl-aerospace.de