Litecool Demonstrates that Narrow Beam LED Packages Are a Real Possibility

Litecool has been working on various LED package designs to give luminaire manufacturers an LED package that doesn’t need any further lensing or reflectors to give the desired beam patterns for lighting applications.

Litecool is well known for their innovative approaches to thermal management but this is their first real development in optical technology and it looks like it could be pretty useful for lighting manufacturers. Nearly all LED packages come with a near Lambertian emission leaving the luminaire manufacturers to work out how to shift that into something useful for their application. This gives both an efficiency and financial cost which Litecool believes they can eliminate with their packages.

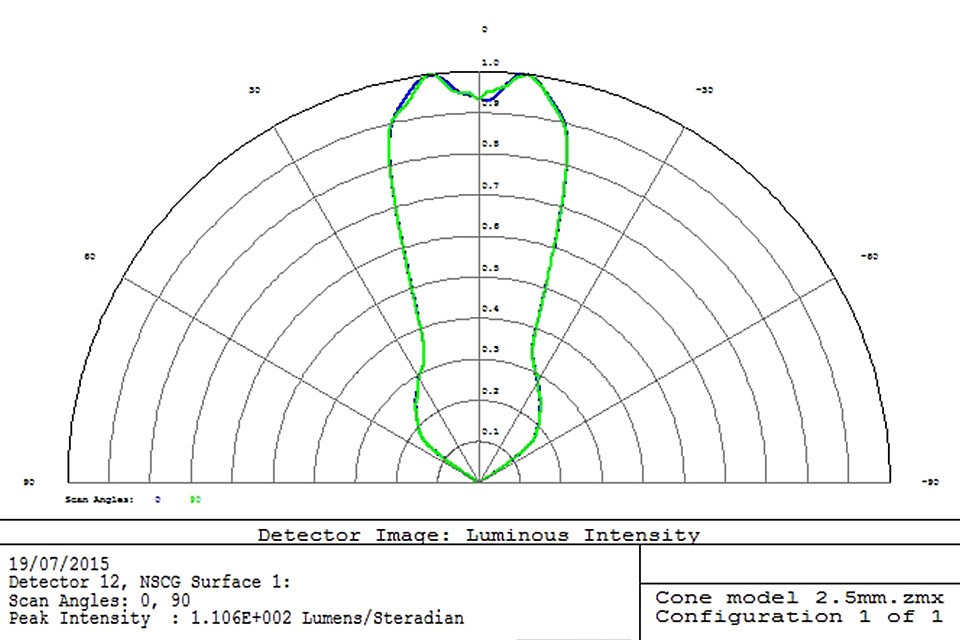

Litecool designs and develops LED COBs and packages from scratch. That means they can change the optical surfaces within the package allowing for different emission patterns. A recent project completed by Litecool has shown that with minor changes to these surfaces they have been able to produce a 36 degree spot with an efficiency above 90%. The project is set to continue and will look to bring the beam angles down to levels suitable for the majority of lighting applications including spot lights. It is expected that Litecool will incorporate this technology within the Lumen Block product range due out next year.

“This is the first iteration and it looks promising. We will be able to reduce beam angles down to around 20 degrees with about 90% efficiency. It doesn’t cost much to make a few design tweak in our packages so it looks like we are going to be able to offer specific beam patterns directly from our LED packages with greater efficiency and lower system costs than what can be achieved at the moment.” James Reeves, CEO, Litecool.

About Litecool:

Litecool (http://www.litecool.co.uk) are leaders in thermally efficient LED packaging and thermal design. By focusing on thermal performance engineering at package level they have helped their customers to achieve breakthrough performance in lumen density, efficiency and reliability enabling a new generation of luminaires which are sleeker, cooler and more cost effective.