Research for OLED mass production

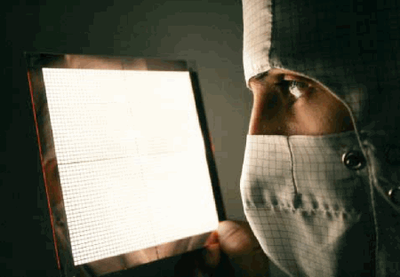

The development of cost-effective processes for volume production of organic light emitting diodes (OLEDs) is the focus of the research work carried out under the CombOLED project. “The objective of this project, which is being funded by the EU and coordinated by OSRAM, is to create the necessary conditions for introducing the new light sources into lighting applications”, said Bernhard Stapp, Head of Solid State Lighting at OSRAM Opto Semiconductors.

This includes methods for cost-effective printing of new component architectures for large-format transparent light sources. As an innovation driver on the LED market and a pioneer in the mass production of semiconductor components, OSRAM Opto Semiconductors is bringing valuable know-how to the EU project.

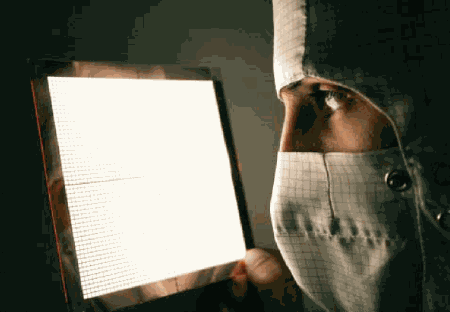

Because OLEDs are ultra-thin, super-light, impressively bright and consume very little energy they are likely to change the lighting market for ever. Experts anticipate that the market will be worth billions from 2015. These flat panel lights have excellent technical characteristics. They last more than 10,000 hours, offer high luminance (1000 cd/m²) and have an efficiency of 40 to 60 lm/W. However before they can conquer the mass market, such as general lighting applications, cost-effective production techniques need to be developed.

Flat light of the future

OLED light sources are complementary to the vast majority of existing light sources. Their major strengths are where their special properties as flat light sources with high quality of light are appreciated, such as in lighting canopies, light partitions and windows that become light sources themselves after the sun goes down. With their pleasant diffused light, OLEDs will soon be appearing in the premium design segment. Architecture and effect lighting and the general lighting market will follow as soon as OLEDs can be manufactured in large quantities at reasonable cost and are scalable.

The CombOLED project is part of a broad initiative by the European Union in the Seventh Framework Program (FP7). For more information go to www.comboled-project.eu

OSRAM Opto Semiconductors is coordinating the work of numerous partners in the CombOLED EU research project for developing cost-effective production technologies for OLEDs.

PRESS CONTACT:

Marion Reichl

Press officer OSRAM Opto Semiconductors

Tel. +49 941 850 1693

Fax +49 941 850 444 1693

email: marion.reichl@osram-os.com