The Future of OLED Lighting

Organic light-emitting diodes (OLEDs) are currently a hot topic in the lighting industry. With major companies such as Osram, Philips, and General Electric displaying prototype products and announcing commercial availability of OLED panels for prototype lighting applications, it is difficult to ignore the industry buzz: “OLEDs are the future of lighting!”

Ten years ago, the industry buzz was, “semiconductor LEDs are the future of lighting!” Today, solid-state lighting (SSL) has become a commercial reality, and it may well overshadow fluorescent lamp technology in the future. However, industry should have learned an important lesson along the way:

People do not buy technology; they buy luminaires.

The importance of this lesson cannot be overstated. Referring to the IES Lighting Handbook, a luminaire is defined as:

Luminaire (light fixture): a complete lighting unit consisting of a lamp or lamps and ballast(s) (when applicable) together with the parts designed to distribute the light, to position and protect the lamps, and to connect the lamps to the power supply.

Architectural lighting has always been about more than just the lamp technology. People rely on the luminaire to properly distribute the light, both to provide desirable levels of horizontal and vertical illuminance, and to control visual glare. Lighting designers specify - and people buy - luminaires.

The lesson learned with solid-state lighting is that advances in LED technology were important only within the context of SSL luminaires. This applies equally to OLED technology. In particular, one needs to look beyond the technology and ask what it is that an OLED luminaire needs to do.

OLEDs in Review

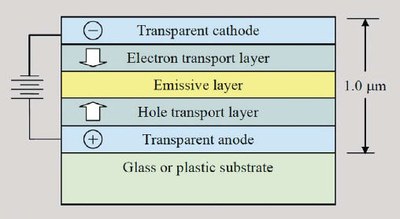

A typical OLED device consists of laminated organic thin films sandwiched between two electrodes and deposited on a glass or plastic substrate (figure 1). When a voltage is applied to the transparent electrodes, the current flow through the organic layers generates light as the electrons and holes recombine in the emissive layer.

If this looks familiar, it is because the principle of operation is identical to that of semiconductor LEDs. The transport and emissive layers are the organic equivalent of the indium gallium nitride (InGaN) thin films used in blue and green LEDs.

There are, however, important differences. While semiconductor LEDs are limited in size to roughly a Square millimeter or so, organic LEDs can (in principle) be fabricated by the Square meter using various manufacturing techniques. Moreover, the plastic substrates can be flexible.

Figure 1 - Typical OLED device

Depending on the choice of organic materials for the emissive layer, OLEDs can be designed to emit any color, including white light with various color temperatures. This, in combination with high luminous efficacy and long lifetimes, reputedly make OLEDs ideal candidates for architectural lighting applications.

As seen with semiconductor LEDs, having light sources with high luminous efficacies and long lifetimes is only the beginning of the story. Lighting specialists need to consider how OLEDs will function as light sources in luminaires.

Optical Characteristics

From a luminaire design perspective, luminary manufacturers are interested in the following optical characteristics of any light source:

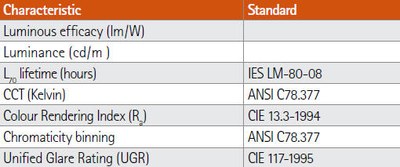

Table 1 - Light source optical characteristics.

OLED manufacturers today typically quote three parameters for their white light products: luminous efficacy (lm/W), luminance (cd/m ), and lifetime (hours). The first two are familiar, but some care needs to be taken with lifetime values.

As defined in IES LM-80-08, the rated lumen maintenance life Lp is the “elapsed operating time over which the LED light source will maintain the percentage, p, of its initial light output.” For lighting display purposes, the L50 (50% lumen maintenance) value is used, while for architectural lighting the L70 (70% lumen maintenance) value is required.

Reflecting OLED’s heritage as a display technology for television and mobile devices, many manufacturers state or assume L50 for their lifetime values. Converting these into L70 values however is easy - just divide the L50 value by two.

Six months ago, the state-of-the-art for commercially available white light OLED lighting panels featured 15 lm/W luminous efficacy, 1,000 cd/m2 luminance, and an L70 lifetime of 5,000 hours. However, OLED technology is advancing rapidly. For example, OLED manufacturer Visionox (www.visionox.com/en) has demonstrated prototype desk lamps featuring white light OLEDs with 40 lm/W and an L70 lifetime of 50,000 hours.

Figure 2 - Visionox prototype desk lamps.

Applying Haitz’s Law (which successfully predicted that LED luminous intensities would double every 36 months), an optimist might reasonably conclude that architectural OLED luminaires are “just around the corner.” (The OLED manufacturers themselves are predicting another three to five years.) However, this begs the question: what is an OLED luminaire?

Lighting Wallpaper

Many OLED manufacturers do not see their products as being used as lamp replacements. In a recent interview with www.dvice.com, OLED scientist Anil Duggan of GE Research said:

“The big fantasy product that lighting designers always talk about is lighting wallpaper. Some lighting professionals want all offices and homes to have this very flexible light source. Flexible means a mechanically flexible light source that one can just paste wherever wanted and turn it on.”

The question is, does this make sense? Will lighting designers and, more importantly, consumers, accept “lighting wallpaper”? We have, after all, spent over a century designing and specifying luminaires that control the light emitted by bare lamps, mostly while shielding the lamps from direct view. Will users accept such a radically different design paradigm?

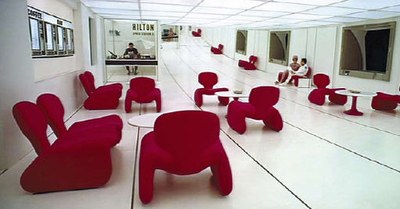

To answer this, a look back fifty years to a time when “luminous ceilings” were in vogue, can help. These consisted of white plastic diffusion panels backlit by linear fluorescent lamps. At the time, they were popular for residential kitchens and (in the movies) futuristic space stations (figure 3). Today, you will be hard-pressed to find any examples - most people do not like them.

Figure 3 - Stanley Kubrick’s 200 - A Space Odyssey.

One notable exception is the Modern Wing of the Art Institute of Chicago, where the soft and essentially shadow-free lighting is well-suited for displaying sculptures and paintings (figure 4). For most applications however, lighting with directionality and shadows to define the visual environment is preferred. A typical counter example is a uniformly overcast sky. While the horizontal illuminance may be 50 to 100 times greater than what is expected for indoor environments, people often complain about the weather being “dark and dreary”.

Figure 4 - Art Institute Chicago Modern Wing (see LpR 19 magazine).

Whether OLED manufacturers can produce lighting wallpaper or luminous ceiling panels is immaterial if there is no significant market for their products.

While people may not accept lighting wallpaper or luminous ceilings, there is certainly a market to replace the millions of linear fluorescent lamp troffers in existing office buildings throughout the world.

Energy-efficient OLED panels as retrofit luminaires would seem to be an ideal solution. There is, however, another problem: visual glare.

Visual Glare

Linear fluorescent troffers are designed to limit their luminous intensity distributions at high viewing angles in order to prevent visual glare in the field of view. ANSI/IESNA RP-1, for example, specifies the maximum intensity to range from 300 cd at 65 degrees to 60 cd at 85 degrees. CIE 117 is even more specific with its Unified Glare Rating (UGR) for direct luminaires.

To quantify this issue, Lighting Analysts’ AGi32 was used to model two empty rooms measuring 24 x 24 meters with 64 1x4-foot direct linear fluorescent troffers. In the first model, used photometric data for a typical commercial luminaire, while for the second model a hypothetical 53x7-inch OLED panel with a luminance of 3,700 cd/m2 was used to produce the same horizontal workplane illuminance of 320 lux.

For the first model, the UGR values rarely exceeded 18 (“acceptable” visual glare). For the second model, the UGR value was 22 to 24 (“unacceptable” to “just uncomfortable”) throughout the floor space, regardless of viewer orientation. (Somewhat surprisingly, the intensities of the OLED panel were 283 cd at 65 degrees and 58 cd at 85 degrees, which satisfied RP-1 requirements.)

Quite simply, it is not possible to employ OLED panels as replacements for direct linear fluorescent troffers without some form of optical control to limit their luminance at high viewing angles. Unfortunately, the only way to do this without sacrificing some of the light emitted by the panels is to increase their luminance to that of T8 linear fluorescent lamps - 10,000 cd/m2.

It is possible that OLED panels can be used as light sources in suspended indirect linear luminaires, but these typically require batwing luminous intensity distributions to avoid unsightly “hot spots” on the ceiling. Past experience in designing such luminaires indicates that OLED panel luminances on the order of 10,000 cd/m2 will still be required.

Color Issues

White-light OLEDs typically employ different electrophosphorescent materials to generate red, green, and blue light (Figure 5). By balancing the light output from each material, the OLED manufacturer can adjust the correlated color temperature (CCT) over a wide range. To meet the expectations of the architectural lighting market, this range should be within the range of 2,700 to 6,500 Kelvin (ANSI C78.377). The problem with this approach is that each electrophosphorescent material has a different L70 lifetime, with blue OLED materials typically half that of red and green OLED materials. As the OLED panels age, there will inevitably be significant color shifts.

This is not an important issue for OLED television displays, as each pixel color is driven independently by the video controller. All that is required is to occasionally adjust the display color balance. For white light OLED panels however, there is no color control. As a result, the panels may exhibit unacceptable color shifts long before their L70 lifetime is reached. (A rough calculation indicates that this may happen after a lumen depreciation of only two to three percent.)

Figure 5 - Typical white light OLED spectrum (see LpR 19 magazine).

What constitutes an “unacceptable” color shift? ANSI C78.377 permits white light LEDs to have variations in chromaticity within the limits of 7-step MacAdam ellipses. This may be compared with ANSI C78.376, which specifies smaller 4-step MacAdam ellipses for linear and some compact fluorescent lamps.

ANSI C78.377 implicitly recognizes the technical difficulties of chromaticity (“color”) binning for semiconductor LEDs, which is why it allows 7-step MacAdam ellipses. Seen side-by-side however, two colors that are seven MacAdam ellipses apart are easily distinguishable. If OLED panels are intended to be viewed directly, then 4-step MacAdam ellipses will likely define the limits of acceptable color shifts.

One potential solution to the problem of color shifts is to employ narrow stripes of red, green and blue OLED materials with separate electrical drivers for each color and optical feedback, similar to what is done with high-end SSL luminaires with RGB LEDs. However, this takes away from the simplicity of OLED panels.

Conclusion

Regarding the architectural lighting requirements for future OLEDbased luminaires, visual glare and color shifts with aging are important, but not the only issues. There are other factors that should be taken into account, for example CIE Colour Rendering Indices (CRI) and luminance uniformity. Low voltage power supply and thermal issues must be addressed, too. (Claims of “no heat” for OLEDs, notwithstanding whatever electrical power that is not converted to light is necessarily converted to heat.)

While the lighting industry is encouraged by the ongoing development of OLED technology, there is a risk that the OLED manufacturers may not fully appreciate the needs of the architectural lighting industry.

Reasonable doubt is advisable that the availability of lighting wallpaper and luminous ceiling panels will result in a paradigm shift towards radically different lighting designs. The technology to create such designs has been available for over half a century, and they are not at all popular.