Low Pressure Molding Technology for Lighting Electronics | Henkel’s Technomelt

Henkel’s Low Pressure Molding technology for encapsulating electrical and electronic components in its Technomelt polyamide adhesive molding compounds is increasingly being adopted for lighting, electronic components, power and industrial automation, and HVAC applications. The technology offers numerous economic, process control, design and environmental advantages over alternative systems such as potting with reactive resin systems and high-pressure injection molding.

Specialized polyamides ensure long-term high performance in IOT Industrial Electronics applications

Various process advantages

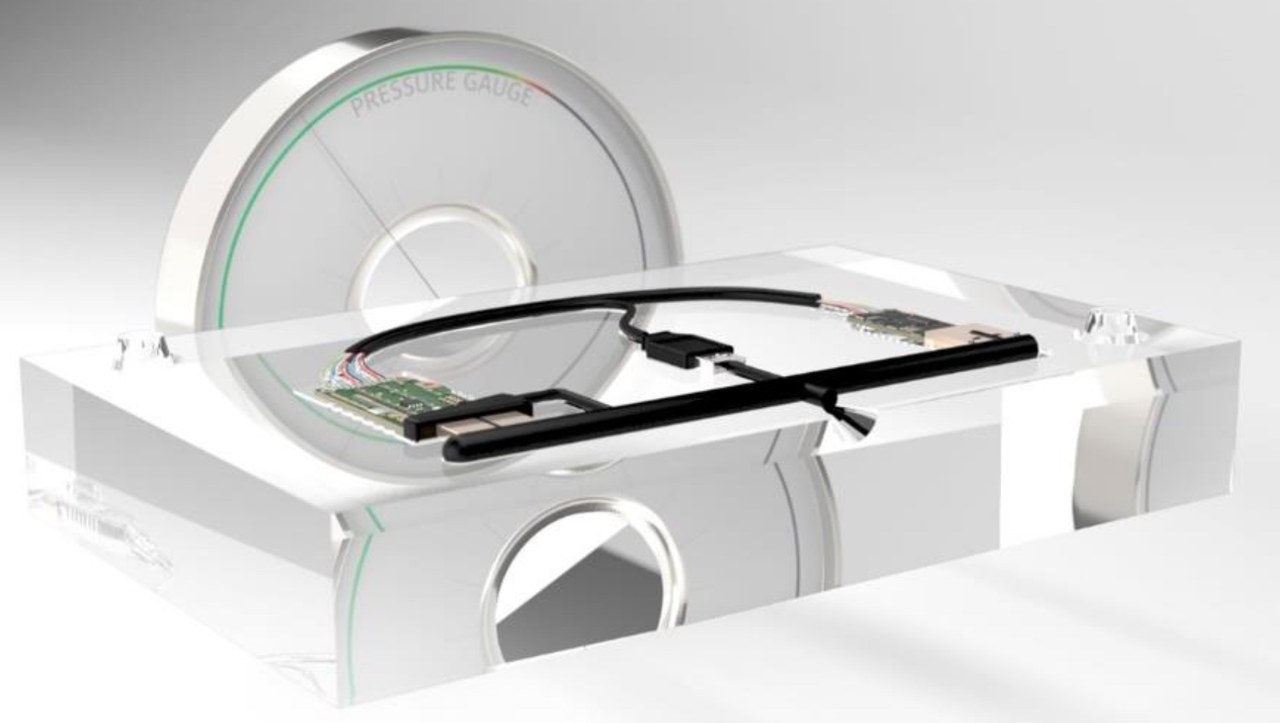

Technomelt Low Pressure Molding (LPM) technology was invented some 30 years ago by Henkel (formerly called Macromelt Molding). The technology enables the quick encapsulation of delicate components by using specialized polyamides in combination with standard processing equipment and low-cost molds. Because the material is injected at a lower pressure compared to conventional injection molding processes, and non-abrasive materials are used, risk of damage to the electronics during the encapsulation process is far lower.

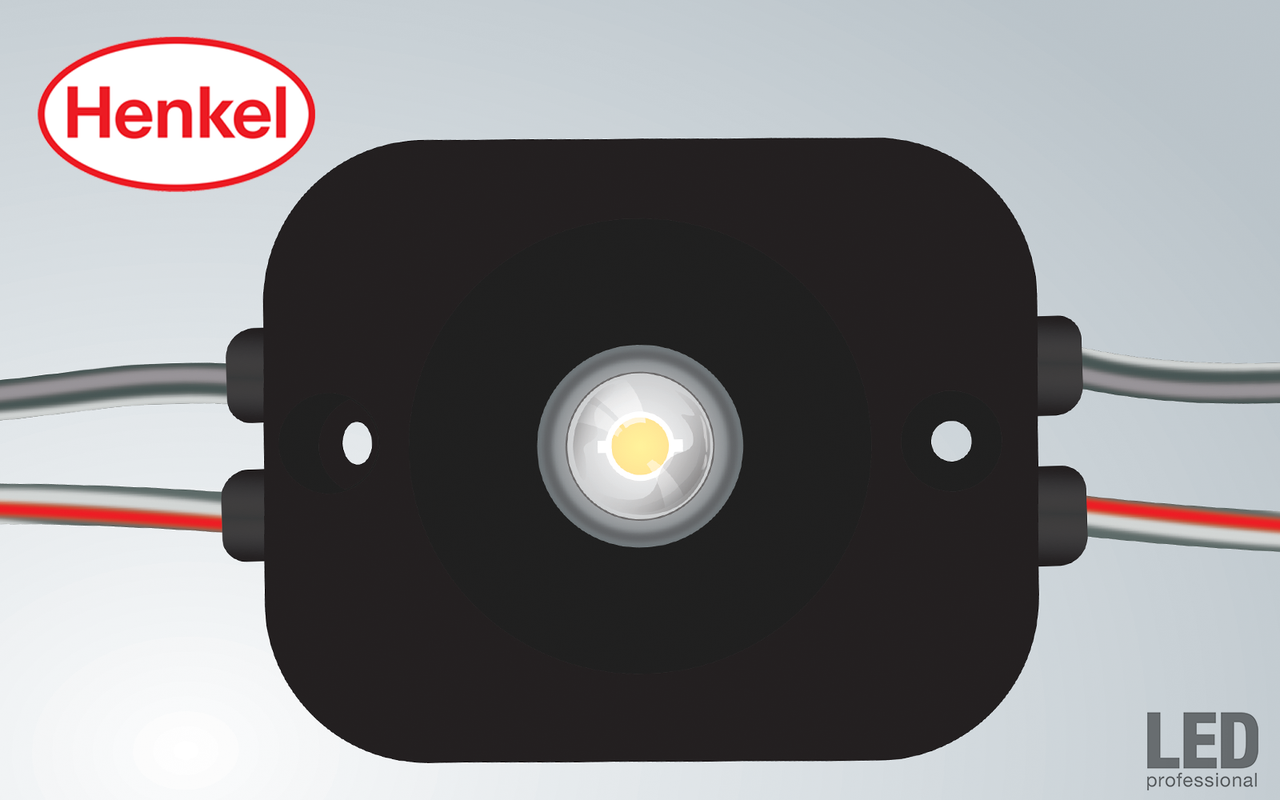

Figure 1: Pressure molding process – the bare electronics are inserted into a predesigned mold set. Technomelt encapsulates electronics at low pressure. After molding, parts get tested and moved to final assembly. (Photo: Henkel, PR089)

The technology is particularly adept at encapsulating discrete areas in complicated assembly where wiring is attached to a printed circuit board (PCB), PCBAs and other rigid component. One reason for this is that Technomelt resins, which are all unfilled, are resistant to high stresses and at the same time very flexible.

Matthew Hayward, Global Key Account for Power & Industrial Automation at Henkel highlights: “I see Technomelt as an exciting part of our Circuit-Board Protection portfolio. It offers many unique advantages that traditional potting or conformal coating is not able to provide. It is particularly well suited to high-mix low-volume applications where throughput is key. The ability to apply this material only where is needed is a huge benefit. This enables one to ‘skyline’ an application (encapsulating only the components that require protection), or to significantly reduce the weight due to substantially less material usage.”

"There are many developments pushing up requirements for high-quality, low-cost component encapsulation. We at Henkel believe Technomelt Low Pressure Molding technology is an important part of the answer to these needs."

– Michael Otto, Key Account Manager Engineering Adhesives for Low Pressure Molding at Henkel

The encapsulating material provides exceptional electrical insulation, as well as resistance to a broad range of chemicals, extreme thermal cycling across high and low temperatures, and vibrations. The internal electronics are fully protected against outside elements, including ingress of water and dust, and long-term UV exposure.

Michael Otto, Key Account Manager Engineering Adhesives for Low Pressure Molding at Henkel explains: “Unlike traditional two-component reactive potting compounds, the polyamides used in the Technomelt Low Pressure Molding process are single-component thermoplastics, molding cycle times are shorter, and there are no emissions of volatiles. Whereas conventional potting can take as long as 24 hours to complete, the Technomelt Low Pressure Molding process has a cycle time that can be as short as 30 seconds.

High sustainability

Henkel Technomelt polyamide resins are compliant with the European RoHS (Restriction of Hazardous Substances) Directive and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations. “An additional important environmental feature of these polyamides, and one that is increasingly appreciated, is that they are largely bio-based, with up to around 80% of their content coming from renewable vegetable sources,” Otto adds.

Henkel offers a range of Technomelt Low Pressure Molding resins that have been formulated for specific applications. Some, for example, have extra thermal resistance, others have improved toughness, or especially good adhesion to particular substrates.

Efficient use of material

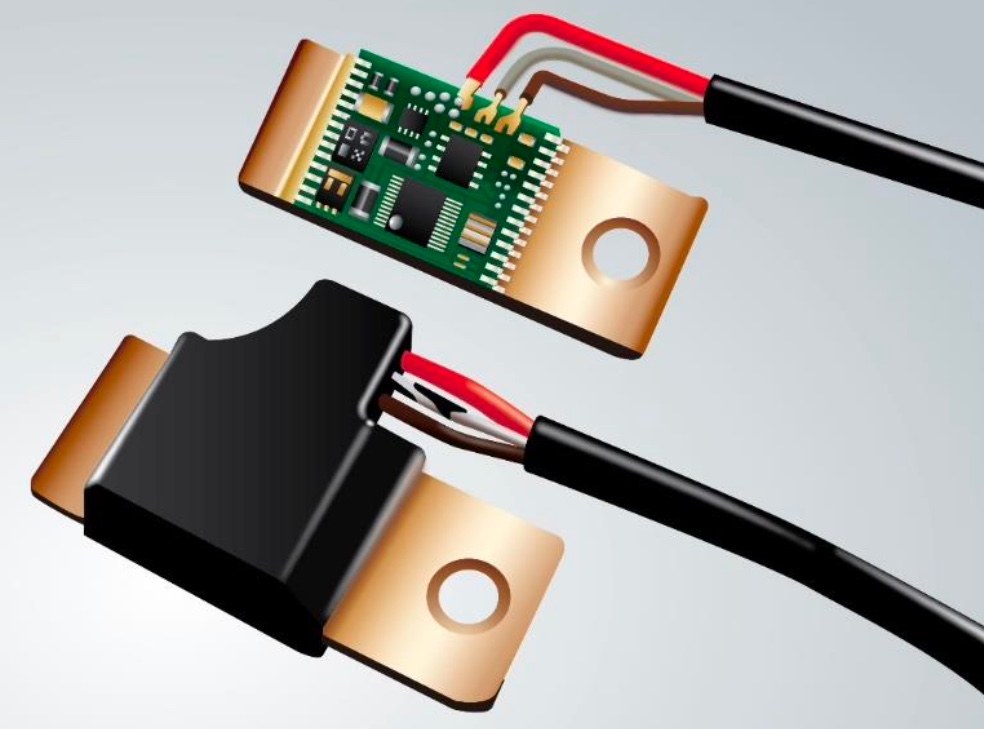

An advantage of Technomelt Low Pressure Molding over traditional potting systems is that it is much more economical in the amount of material it uses in the finished part. In potting operations, the normal approach is to build a box around the component to be encapsulated, and then fill the box until the component is covered.

With Technomelt Low Pressure Molding, the component is placed into a mold that has a cavity geometry similar to that of the component, so that when the polyamide is injected, it forms a skin around the component that is more or less the same thickness at all points. This means that the amount of encapsulating material used per shot can be considerably less.

Figure 2: Battery sensor circuit board before and after low pressure molding process. Electronic parts get protected against moisture, chemical exposure and high temperature. (Photo: Henkel, PR089)

Costs of mold production are relatively low, especially as they are often made out of aluminum, which is much less expensive than tools made out of steel used in high-pressure injection molding. In recent years, even more cost-effective additive manufacturing (also known as 3D printing) techniques have also been adopted to make the molds.

Providing value to various markets

The need for efficient low pressure encapsulation of electronics has never been as great as it is today. The Internet of Things (IOT) and Industrial Internet of Things (IIOT) depends on a foundation of sensors and associated electronic connections and components to support all sorts of devices in the home, at work, and on the move. This trend has also led to increased network connectivity demands for data and power cables and connectors that function in the harshest environments. In the world of healthcare, patient diagnostics and sensing in real time require new electronic devices like wearable devices that are used in and outside of controlled medical environments. Technomelt Low Pressure Molding responds to all of these trends.

Jason Spencer, Henkel’s Medical Market Segment Manager, notes: “Patient diagnostics and sensing in real time require new electronic devices that are worn in and outside of a controlled medical environment. Wearables for vital sign monitoring are becoming more important in patients’ everyday lives as healthcare becomes more digitally connected.”

For certain types of medical applications, Technomelt can also be used in applications that go beyond encapsulation of electronics. For example, it is suitable for attaching flexible tubing in liquid delivery systems, since it does not distort the tubing and provides a permanent, leakproof junction. Henkel introduced, Loctite PA 6951, specifically for this purpose. Loctite PA 6951 has been tested to Henkel’s protocols based upon ISO-10993 biocompatibility standards, with certificates available on request.

Partnerships with equipment suppliers

In collaboration with partners producing processing equipment around the world, Henkel provides a total solution for low pressure injection molding. “These partners are critical for our success,” says Otto. “Technomelt is a total system that brings together materials, machines, molds, and technical service and engineering. Our partners have their own sales forces, which adds to our ability to access and assist the vast global market.”

Additionally, Otto highlights “there are many developments pushing up requirements for high-quality, low-cost component encapsulation. We at Henkel believe Technomelt Low Pressure Molding technology is an important part of the answer to these needs.”

Technomelt is registered trademark of Henkel and/or its affiliates in Germany and elsewhere.

For further information:

https://www.henkel-adhesives.com/at/en/about/our-brands/technomelt.html

___

© 2021 LED professional / Luger Research e.U.