Epoxy Features Very Low Coefficient of Thermal Expansion

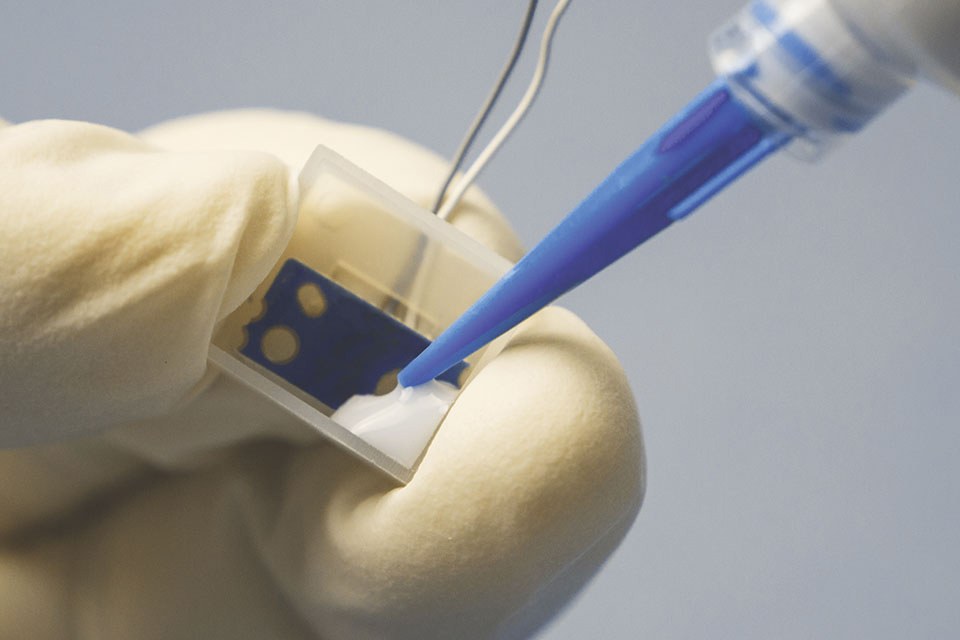

Master Bond EP30LTE-2 has been developed for joining dissimilar substrates exposed to thermally or mechanically induced stresses. It can be used for sealing, coating and encapsulating, especially for small to medium sized castings where a very low coefficient of thermal expansion (CTE) is required.

EP30LTE-2 is a highly dimensionally stable epoxy system with low linear and volumetric shrinkage upon curing. The compressive strength of the cured material is 24,000-26,000 psi and its CTE is very low at 10-13 x 10-6/in/in/°C. It is a reliable electrical insulator featuring volume resistivity of more than 1015 ohm-cm. EP30LTE-2 meets NASA low outgassing specifications and features a combination of physical properties making it ideal for applications in aerospace, optical, electronic and specialty OEM industries where these requirements are critical.

EP30LTE-2 is a two part epoxy which obtains optimal properties when cured overnight at room temperature followed by a heat cure for 2-4 hours at 150-200°F. This system offers moderate flow characteristics with a mixed viscosity ranging from 70,000 to 100,000 cps. In addition to standard packaging units of ½ pint, pint, quart, gallon and 5 gallon kits, the epoxy is available in premixed and frozen syringes.

For additional information, please visit https://www.masterbond.com/tds/ep30lte-2 or contact Master Bond at technical@masterbond.com

About Master Bond:

Master Bond formulates adhesive, sealant, and coating solutions for LED lamp and luminaire assembly applications. Our epoxies, silicones, UV and LED curing compounds offer a combination of properties to meet stringent testing requirements for reliable long term performance. Select systems absorb stress, resist solvents and fuels, and offer thermal conductivity, a low refractive index, low ionic content and high thermal stability. Master Bond provides unmatched technical expertise and customer support. - www.masterbond.com