Quality Inspection for LED Module Manufacturing - Precise, Reliable, Reducing Scrap and Costs

In terms of energy savings and energy efficiency, LED (light-emitting diode) is dominating private as well industrial illumination more and more. LED is used to illuminate offices and private living areas, vehicle lightning, advertisings, street lighting, etc. In addition, LED technologies have conquered already into technology fields as entertainment electronics, aerospace, fibre optic based communica-tion, medical areas, optical inspections, etc. With low weight, variable light colours, long-life at lower cost, etc., LED will remain as a future based technology.

The challenge:

As LED these days is categorised as a bulk product, costs of production and related productivity are mandatory. Even for those bulk items, quality is required, especially for the area where safety and reputation plays an essential part. To perform reproducible photometric and colourimetric measure-ments the International Commission on Illumination (CIE) provided requirements defined in the standard of CIE S 025/E:2015. The standard aims in particular to cover measurement methods for testing the compliance of LED devices with the photometric and colourimetric requirements of LED performance standards issued by IEC/TC 34. And here the particular challenge occurs: Testing of LED modules as an extra quality process influences the costs directly.

The solution:

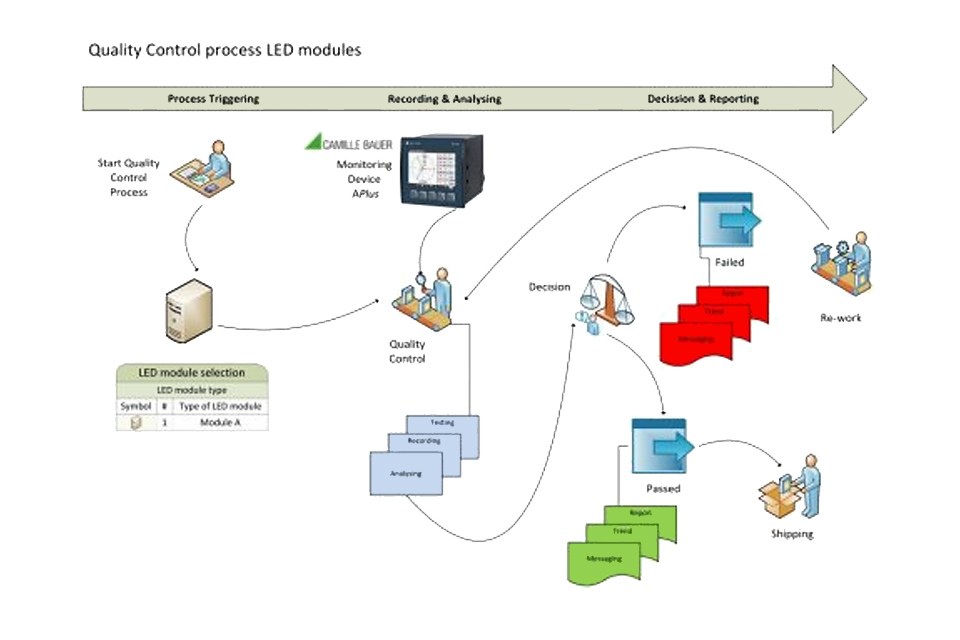

To remain marketable, testing of LED modules shall be efficient, unsophisticated, reliable as well extremely cost optimised. The APLUS of Camille Bauer perfectly fits to all requirements. APLUS is designed in the way to measure over 3 phases – even with different loads on each phase. Instead of using one costly power meter for qualifying one LED module in a test stage, with APLUS three LED modules can be tested simultaneously. This reduces investment cost as well the demand of space down to one-third against single phase devices.

While the accuracy corresponds to the requirements, APLUS often is much less cost intensive than other used measurement devices in such specific application, and this in addition to an excellent durability. Reducing complexity, besides its three-phase measurement capability, can further be enhanced by means of individual parameter settings. Measurement data can be captured in a straightforward manner during the various production phases, and can be sent to analysing and re-cording software.

Kaistar Lighting confirms:

As one of the leading companies for LED modules, Mr. Zhang from Kaistar Lighting in Xiamen con-firms the benefit of using APLUS from Camille Bauer. Before APLUS was introduced, the operator could test one LED module at a time. Now, with APLUS the efficiency tripled which saves directly time and money. With the integration into a test- and analysing software, testing process is automat-ed and out of this, failure possibility during testing procedure came down to zero.

Further information under: http://www.camillebauer.com/aplus-en

Camille Bauer Metrawatt AG:

Camille Bauer Metrawatt AG is a Swiss medium-sized company for the development and production of industrial measurement equipment. Organised in two business units, Camille Bauer offers customers application oriented solutions in the high-voltage monitoring and position sensoring. The company is part of the GMC-I with headquarters in Nürnberg, Germany and as such with its worldwide representatives is a renowned supplier for the measurement of electrical and energetic parameters. This includes a deep understanding of the needs of the electrical energy generation, distribution of energy as well as the industrial consumers. With its Swiss regard for highest quality and its strong capacity for innovation Camille Bauer Metrawatt AG delivers measurable added value to its customers. More information available from www.camillebauer.com