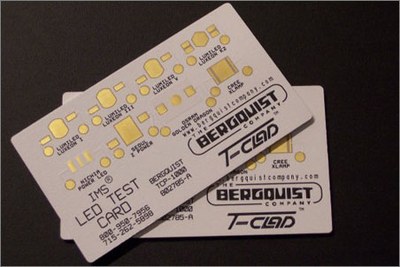

Bergquist announces a new cost-effective thermal management material for High Brightness LED applications

Bergquist takes account to the requirements of HB-LEDs and introduces new circuit board laminate with 3.5 times better thermal performance than epoxy glass-on-aluminium alternatives. Yet most PCB shops with standard multilayer vacuum lamination equipment can process Bond-Ply TCP-1000.

Bond-Ply TCP-1000, a new dielectric material from The Bergquist Company, satisfies the extreme thermal challenges of applications using high brightness LEDs (HB-LEDs). Without proper thermal management techniques HB-LEDs quickly warm-up, reducing their light out-put. Life-time is also related directly to the junction temperature, so the selection of a good thermally conductive substrate helps considerably in reducing the risks of over-heating the HB-LED.

Using Bond-Ply TCP-1000 as a circuit board laminate delivers more effective heat transfer from temperature-sensitive components than standard prepreg materials. It competes effectively with constructions made from epoxy glass-on-aluminium and is equally easy to process in PCB manufacturing.

Bond-Ply TCP-1000, which comes in the form of a Metal Core PCB, offers superior thermal performance over standard FR4 substrates at a highly competitive price. The aluminium base layer comes in standard thicknesses of 1.0 and 1.6mm whereas the circuit-foil is available in 35 μm and 70μm. Other foil thicknesses are available upon request. Laminated panels are available in 18 x 24-inch as well as 20 x 24-inch sizes. Bergquist also offers circuits that are custom configured to specific design parameters. Designed specifically to offer an alternative to various FR4 configurations, Bond-Ply TCP-1000, with a thermal conductivity of 1,5W/m-K, has a thermal performance that is at least 3.5 times better, supporting the high performance levels needed for applications with increased lumens per Watt while managing the LED junction temperature effectively.

The product’s continuous use temperature range is -40 C to +130 C and it has a dielectric breakdown strength of 5000 VAC minimum. All the electrical, thermal and operating characteristics are in a technical data sheet available from The Bergquist Company’s web site at www.bergquistcompany.com .