High Thermal Substrate Technology & Light Engine Module from Globetronics

CERMEQ is the latest patented high performance thermal substrate developed by Globetronics. Fundamentally, It changes how SSL (Solid State Lighting, or LEDs) are packaged from Level 1 (die level), Level 2 (module) and integrated into products.

CERMEQ’s capabilities include the ability to reduce heat in SSL packages and to achieve cost savings through the reduction in assembly steps. Shortened package R&D cycle time and minimization of tooling cost

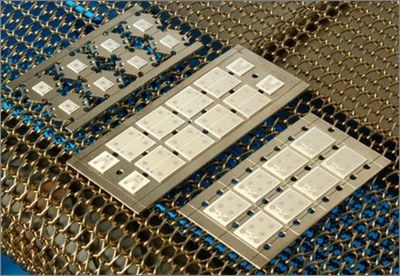

CERMEQ Substrate:

With super low thermal resistant, CERMEQ is suitable for power LED assembly, high performance solar panel as well as other thermal applications in the semiconductor industry. It is an efficient, cost effective and easy to use thermal substrate in SSL application featuring C.O.B capability (Chip-on-Board) and RoHS compliance. Unlike standard MCPCB, CERMEQ (HT Series) can withstand typical AuSn reflow of 310°C which is a common die attach methodology for high performance power SSL.

A package assembled on CERMEQ eliminates the need for a MCPCB (metal cored printed circuit board) and can be directly mounted to secondary heat-sink at product level. This eliminates the need for a SMT (surface mounting technology) process and also results in less stress and a lower manufacturing cost for the LEDs.

The reliability property of CERMEQ exceeds those commonly offered by standard PCB or MCPCB. It constructed with high thermal conductive material. CERMEQ Substrate is able to pass thermal shock/temperature cycle of 2000 cycles (-40°C/100°C, 15-5-15) and Aging Test of 1000 hours of 125°C. Complete assembled Light Engine pass 1000 hours for WHTSL (85RH/85°C), HTSL (125°C), LTSL (-40°C) and HTOL (120-130°C) while WHTOL test is still on-going.

Depending on the design and application, the effective thermal resistant for CERMEQ ranges from as low as 0.2°C/W to 0.5°C/W, one of the lowest in the SSL industry.

CERMEQ LEM (Light Engine Module):

CERMEQ Light Engine Module strikes the optimum balance by utilizing the thermal performance advantages of the patented substrate technology as well as the concept of COB. It’s simplified process eliminates the use of MCPCB assembly, reduces package stress and improves thermal conductivity by doing away with resin / epoxy as a dielectric layer. It’s ability to withstand severe temperature cycle / aging stress and thermal shocks without facing delamination demonstrates its uniqueness as one of the new outstanding substrates available in the marketplace today.

About Globetronics:

Founded in 1991 by 2 ambitious entrepreneurs, Globetronics has grown rapidly over the last 12 years from one humble 20,000 sq.ft. rented facility to ten buildings covering more than 600,000 sq.ft., with over 2,500 employees. The major shareholders of Globetronics include Malaysian Technology Development Corporation (MTDC) and Penang-based General Produce Agency (GPA). Globetronics was listed on the Kuala Lumpur Stock Exchange (KLSE : 7022 GTRONIC) on 3 November 1997.

Vision: To Be The Global Business Partner of Choice In Niche Products And Services.

Mission: To Deliver Continuous Growth And Breakthroughs In Business Performance With Total Customer Satisfaction.

For additional information visit http://www.globetronics.com.my .