Sumitomo Metal Mining & Tohoku University Research Team Develop New Oxide-based Red Phosphor

Sumitomo Metal Mining Co., Ltd., working in collaboration with a research team from Tohoku University’s Institute of Multidisciplinary Research for Advanced Materials (IMRAM) headed by Professor Masato Kakihana, has succeeded in developing a new silicon-containing oxide-based red phosphor1 for use in white LEDs2. The new phosphor can be manufactured less expensively than earlier red phosphors and is expected to contribute to higher performance in white LEDs as sources of illumination.

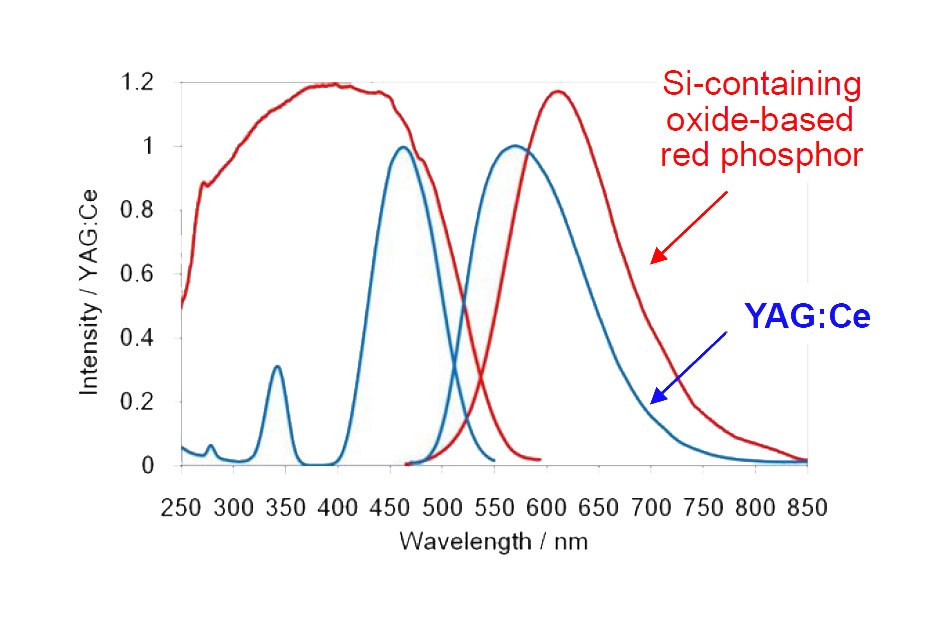

White LEDs are widely used as backlight illumination sources in LCD panels owing to their low power consumption and long service life. Today, however, they are also coming into widespread use as sources of illumination for lighting applications, and this market is expanding rapidly. Today, most white LEDs in usage combine a blue LED and a yellow phosphor (YAG:Ce), but the obtainable white light offers insufficient color rendering3 for use as a source of illumination. Achieving fine natural hues has posed a challenge, and a solution has been sought through simultaneous usage of yellow and red phosphors. To date, the only commercially viable red phosphors available have been nitride-based, and these have been costly owing to the need for a special manufacturing process involving firing at high temperature and pressure levels. Less expensive red phosphor has been sought in order to enable white LEDs to replace fluorescent lamps as light sources of diverse description.

The collaborative R&D program succeeded in developing the first oxide-based phosphor containing silicon (Si) capable of emitting light across the orange-to-red spectrum (600-625 nm)4. The phosphor’s host crystal is a composite oxide of alkaline-earth and Si, with europium added as a light-emitting element; it emits red light by blue LED irradiation. The new phosphor can be manufactured at lower cost since production can be carried out at lower temperatures than nitride-based phosphors and at normal pressure levels, eliminating the need for expensive equipment. Going forward they are expected to come into use in white LEDs answering the call for sources of illumination offering greater color rendering.

Another epochmaking aspect of this R&D is the use of a proprietary aqueous solution method5 whereby a water-soluble silicon compound – propylene glycol-modified silane (PGMS)6 – is applied to achieve synthesis of a Si-containing oxide-based compound. Going forward, further usages of PGMS can be expected to accelerate the development of high-luminance and other new phosphors.

To date SMM has undertaken the development of technology for manufacturing high-luminance Si-containing oxide-based phosphors and technology for coating phosphor surfaces with a thin film in order to further enhance their moisture resistance and optical properties. These technologies have been applied in the newly developed oxide-based red phosphor, and plans will now focus on providing film-coated oxide-based red phosphors to the market.

The technological development reported here is a direct outcome of joint R&D conducted in line with the cooperative agreement concluded between SMM and Tohoku University in October 2010. Further joint research will continue to go forward under this collaborative initiative.

For additional information please visit http://www.smm.co.jp/E/