AsianSignals' Rebel Square - A Simple Exercise in Common Sense Design for Lower Cost

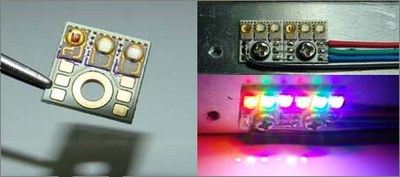

AsianSignals, manufacturers of LED electronics, has released a new, low cost, easy to mount, reliable product for mounting Luxeon Rebel LEDs.

Low Cost:

In the case of the Rebel, Luxeon specifically states that the LEDs do not need an exotic insulation. The Rebel Square is build on standard well understood copper RF4 technology. The top and bottom layer are joined by heavily plated vias through the board. This approach is a standard in the industry and it is a time tested approach to thermal management.

Superior heat sinking design with heavy copper vias and copper base:

The physics are pretty simple. Very few metals beat copper for heat sinking capability. The longitudinal channels in the copper serve as "wells" to help contain excess silicone heat sinking compound. Excess compound can also easily exit through the vias. There is no danger in trapped heat sinking compound putting upward pressure on the board (causing some other boards to warp)

Gold plated for beauty and smoother protective surfaces:

What you see here is a thin gold plating. The plating helps to produce a smoother surface and it protects the copper against oxidation.

Enclosed /captive anchor point:

In our efforts to ensure the very best heat sinking, we also bonded the mounting through hole to the base. This effectively insures the very best in heat transfer by directly involving a metallic screw in the process.

Small footprint:

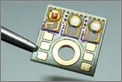

Our product is exactly 12mm by 12mm. It is literally the smallest and most efficient design of a square containing rectangles. These can be lined up for a straight line or placed in groups of square for a very high density solutions.

Easy to solder pads:

If you have previously used Luxeon Stars or other products built on top of aluminum based boards like the Endor Star, then you are aware of how difficult it is to solder wires to them. The solder pads on these aluminum based boards are heat-sinked by the aluminum. Those pad are difficult to warm up under a soldering iron. In our Rebel Square design, we allow the copper pads to be in a more insulated area and so soldering to them in just like soldering on a normal circuit board. Soldering is easy, fast, and neat.

Inline series wiring native to the design:

Ever tried to wire an star LED in series? The wires are all over the place. The star design is poor for wiring LEDs in series. This problem is compounded when you want to create a dense arrangement of LEDs. The Rebel Square solves that problem by giving you an easy path for in-lining LEDs.

LEDs easily mounted with manual re-flow hand techniques:

The board is really easy to work with. You can hand solder this board with very simple tools. With solder paste, and a simple hot air soldering station almost anyone can mount the LEDs in their work shop. This further reduces your costs and allows you to make repairs on one LED without throwing away an entire board. With some experimentation you should also be able to apply heat from soldering iron on the bottom of the board and effectively melt the solder paste from below. However, care would need to be taken that you don't transfer solder on to the bottom of the board as you want this board to sit flat against a heat sink.