High efficiency light emitting diode (LED) with optimized photonic crystal extractor

A high efficiency, and possibly highly directional, light emitting diode (LED) with an optimized photonic crystal extractor. The LED is comprised of a substrate, a buffer layer grown on the substrate (if needed), an active layer including emitting species, one or more optical confinement layers that tailor the structure of the guided modes in the LED, and one or more diffraction gratings, wherein the diffraction gratings are two-dimensional photonic crystal extractors. The substrate may be removed and metal layers may be deposited on the buffer layer, photonic crystal and active layer, wherein the metal layers may function as a mirror, an electrical contact, and/or an efficient diffraction grating.

Background of the invention

[0007] 1. Field of the Invention

[0008] The invention is related to light emitting diodes (LEDs), and more particularly, to a high efficiency LED with an optimized photonic crystal extractor.

[0009] 2. Description of the Related Art

[0010] A light emitting diode (LED) is a semiconductor device that emits light in a stimulated manner when electrically biased in the forward direction. This effect is a form of electroluminescence.

[0011] An LED is comprised of a chip of semiconducting material impregnated, or doped, with impurities to create a structure called a pn junction. When biased forwardly, electrons are injected into the junction from the n-region and holes are injected from the p-region. The electrons and holes release energy in the form of photons as they recombine. The wavelength of the light, and therefore its color, depends on the bandgap energy of the materials forming the pn junction.

[0012] As semiconductor materials have improved, the efficiency of semiconductor devices has also improved and new wavelength ranges have been used. Gallium nitride (GaN) based light emitters are probably the most promising for a variety of applications. GaN provides efficient illumination in the ultraviolet (UV) to amber spectrum, when alloyed with varying concentrates of indium (In), for example.

[0013] Unfortunately, most of the light emitted within a semiconductor LED material is lost due to total internal reflection at the semiconductor-air interface. Typical semiconductor materials have a high index of refraction, and thus, according to Snell's law, most of the light will remain trapped in the materials, thereby degrading efficiency. By choosing a suitable geometry for the LED, a higher extraction efficiency can be achieved.

[0014] FIG. 1 is a cross-sectional view of a homogeneous light-emitting material 10 that illustrates that a fraction of the light 12 emitted inside the material 14 is inside the escape cone 16 and can escape the material 10, while a large fraction of the emitted light 18 is trapped and reflected within the material 10. In this situation, the reflected light 18 is referred to as guided light modes, or guided modes, because the light 18 is confined within the device 10 and guided transversely within the material 10.One method for reducing the effects of the total internal reflection is to create light scattering or redistribution through random texturing of the surface of the device, which leads to multiple variable-angle incidence at the semiconductor-air interface of the device. This approach has been shown to improve emission efficiency by 9-30%, as a result of the very high internal efficiency and low internal losses, which allows many passes for light before it escapes from the device.

[0015] FIG. 2 is a cross-sectional view of a semiconductor LED 20 that illustrates this concept, wherein the top surface 22 of the LED 20 is textured, the bottom surface 24 of the LED 20 comprises a reflector, the air has a refractive index of n=1, and the semiconductor material of the LED 20 has a refractive index of n=3.5. The textured top surface 22 of the LED 20 is used to randomize light trajectories in a geometrical optics approach.

[0016] Another method to reduce the percentage of light trapped is to use a Resonant-Cavity LED (RCLED) or Micro-Cavity LED (MCLED). MCLEDs offer opportunities to create solid-state lighting systems with greater efficiencies than existing systems using "traditional" LEDs. As a result of incorporating a gain medium within a resonant cavity, MCLEDs emit a highly compact and directional light beam. The higher extraction efficiency and greater brightness of these devices are the main advantages of these technologies over conventional LEDs.

[0017] Extraction efficiency refers to the ability of the photons generated by a particular system to actually exit the system as "useful" radiation. This higher extraction efficiency is, however, limited to values in the 40% range as the micro-cavity structure also leads to very efficient emission into guided modes and leaky modes. Thus, it would be useful if these guided modes could be extracted.

[0018] As noted above, guided modes are modes that are guided in the device plane due to the index difference between the structure layers. Leaky modes are radiated through the layers, towards the air or substrate-for instance through a DBR. Leaky modes are usually lost as they undergo multiple total internal reflection at interfaces, travelling back and forth within the device, until their energy is dissipated by various loss mechanisms (e.g., metal mirror loss, free carrier absorption, re-absorption by the active layer which recycles energy by re-emission, although with some losses, etc.).

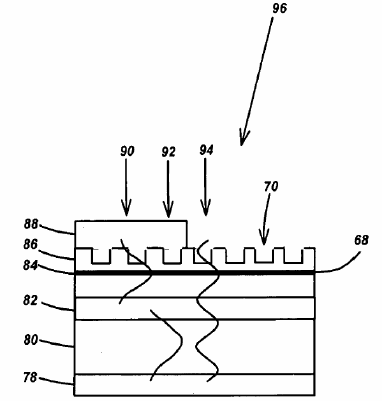

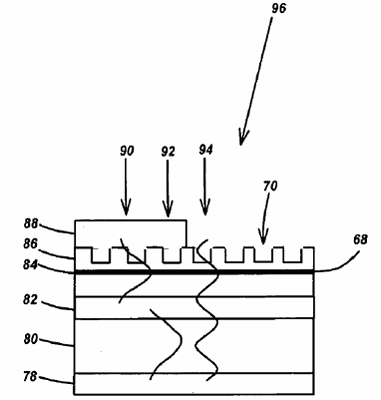

[0019] FIG. 3 is a cross-sectional view of a semiconductor LED 26 that illustrates radiating, guided and leaky modes, wherein the LED 26 includes a substrate 28, a buffer layer 30, and an active layer 32 including quantum wells (QWs) 34. Part of the emitted light is extracted 36 towards the air and forms radiative modes 36, part of the emitted light leaks 38 through the various layers of the device 26 into the substrate 28 and forms leaky modes 38, and part of the emitted light is reflected 40 in the active layer 32 (or in both the active layer 32 and buffer layer 30) and forms guided modes 40.

[0020] To obtain high efficiency LEDs, it is necessary to optimize direct mode emission 36 outside the structure, minimize the leaky mode emission, if such modes are present 38, and, if possible, re-emit the guided mode emission 40. The present invention aims at fulfilling this goal, in structures amenable to easy fabrication.

[0021] FIGS. 4A-4B and 5A-5B illustrate the structures (FIGS. 4A and 5A) and simulations (FIGS. 4B and 5B) of micro-cavity emission, via a bottom metal or distributed Bragg reflector (DBR) mirror, and a single interface with air at the top, in a gallium nitride (GaN) materials system. FIGS. 4B and 5B are angular emission diagrams inside the semiconductor, on a log scale, wherein FIG. 4B shows the emission of the structure of FIG. 4A, and FIG. 5B that of FIG. 5A. For both FIGS. 4B and 5B, the left half of the figure shows the transverse magnetic (TM) emission and its right half shows the transverse electric (TE) polarized emission. Only in-plane monochromatic dipoles are assumed.

[0022] In FIG. 4A, the structure includes a metal mirror 42, and an active layer 44 including quantum wells 46, wherein the structure is a 3[lambda]/4 cavity with the quantum wells 46 placed at [lambda]/4 (48) of the metal mirror 42. In FIG. 4B, arrow 50 shows emission towards the air, while arrow 52 shows emission towards the substrate. Also in FIG. 4B, braces 36 indicate extracted light, and brace 40 indicates guided modes.

[0023] In FIG. 5A, the structure includes a buffer 54, 7 period DBR mirror 56 and active layer 58 including quantum wells 60, wherein the structure is a k cavity with the quantum wells 60 placed at [lambda]/2 (62) of the 7 period DBR mirror 56. In FIG. 5B, arrow 64 shows emission towards the air, while arrow 66 shows emission towards the substrate. Also in FIG. 5B, braces 36 indicate extracted light, braces 38 indicate leaky modes, and brace 40 indicates guided modes.

[0024] Extraction efficiency from these structures is, respectively, in FIG. 4A, 31% and 24% in air, and in FIG. 5A, 44% and 27% in epoxy.

[0025] Difficulties are encountered in most materials systems when attempting to obtain large micro-cavity extraction improvements of LEDs. FIGS. 4B and SB show the emission diagrams from which is extracted the expected efficiency of optimized GaN micro-cavity LEDs, and illustrate the following issues:

(i) The index contrast for materials epitaxially grown is quite limited, in particular for the very important nitride materials. This is why emission into many leaky modes is seen in the DBR mirror 56 structure of FIG. 5A, which make the DBR mirror 56 structure of FIG. 5A less efficient than the metal mirror 42 of FIG. 4A.

(ii) The displayed efficiencies are only possible because very thin structures were considered, leading to low-order cavities (as described in reference 10 below). It is difficult to obtain such thin active layers. For example, it is usually necessary to grow a thick (several microns) buffer layer of nitride on a substrate before growing good quality material for the active layer. While lifting off the nitride materials (buffer layer and active layer) from the substrate is already a delicate operation, there is, in addition, extreme difficulty in obtaining the thinner layers (i.e., further removing part or all of the buffer layer) bounded by good metal mirrors, which would lead to the excellent performance of the thin metal mirror structure shown in FIG. 4A.

[0028] Thus, there is a need in the art for improved LED structures that provide increased light extraction efficiency. In addition, there is a need in the art for improved LED structures that optimize direct emission outside the structure, minimize leaky mode emission, and re-emit guided mode emission. Moreover, there is a need to provide such improved LEDs while retaining a planar structure, in order to render such structures amenable to easy fabrication. The present invention satisfies these needs, and aims especially at the case of LEDs that support numerous guided modes (e.g., LEDs whose thickness can not easily be made thin enough to make them support only one or a few modes). Finally, the present invention can enhance the directionality of light emission, which is a highly desirable property for some applications, such as LCD displays.

Brief summary of the invention

[0029] The present invention discloses a high efficiency, and possibly highly directional, light emitting diode (LED) with an optimized photonic crystal extractor. The LED is comprised of a substrate, a buffer layer grown on the substrate (if such a layer is necessary), one or more optical confinement layers, an active layer including emitting species, and one or more diffraction gratings, wherein the diffraction gratings are two-dimensional photonic crystal extractors. The substrate may be removed and metal layers may be deposited on the buffer layer and active layer, wherein the metal layers may function as a mirror, an electrical contact and/or a diffraction grating.

Claims

1. A light emitting diode (LED), comprising:

(a) a substrate;

(b) an active layer formed on the substrate, wherein the active layer includes one or more light emitting species;

(c) one or more optical confinement layers formed under or around the active layer, wherein the optical confinement layers tailor a structure of guided modes within the LED; and

(d) one or more diffraction gratings formed on the optical confinement layers, wherein the diffraction gratings are two-dimensional photonic crystals that extract light from the LED.

2. The LED of claim 1, further comprising a buffer layer formed on the substrate, wherein the active layer is formed on the buffer layer.

3. The LED of claim 1, wherein the diffraction gratings direct emissions outside the LED and convert guided modes into extracted light.

4. The LED of claim 1, further comprising one or more layers deposited on one or both sides of the LED, wherein the layers function as a mirror, electrical contact and/or diffraction grating

5. The LED of claim 1, where the optical confinement layers enhance light extraction by the photonic crystals.

6. The LED of claim 5, wherein the optical confinement layers help to excite those modes localized above the optical confinement layers.

7. The LED of claim 1, wherein light is primarily emitted into modes that interact with the photonic crystals, so that guided modes that are usually lost are diffracted outside the LED.

8. The LED of claim 1, wherein the photonic crystals cross the light emitting species in the active layer.

9. The LED of claim 1, wherein the photonic crystals are situated within one or a few optical lengths from the light emitting species in the active layer. 10. The LED of claim 1, wherein the LED retains a planar single layer structure. 11. The LED of claim 1, wherein the photonic crystals include a taper comprised of variable hole lines.

12. The LED of claim 11, wherein the taper comprises one or more periods of modified holes, and the modified holes have a variable hole depth, variable hole period, or variable hole diameter.

13. The LED of claim 1, wherein characteristics of the photonic crystals are varied along its structure, so as to modify properties of the photonic crystals.

14. The LED of claim 1, wherein a light generation region coincides or overlaps with the photonic crystals, so that guided light does not suffer from reflexion or scattering at an interface to the photonic crystals region.

15. The LED of claim 1, wherein a position of the light emitting species is finely tuned, so as to precisely control its emission properties.

16. The LED of claim 1, wherein, by suitable tailoring of a guided modes structure, light diffraction by the photonic crystals occurs in a given range of directions, thereby forming a highly directional light source.

17. A method of fabricating a light emitting diode (LED), comprising:

(a) forming an active layer on a substrate, wherein the active layer includes of one or more light emitting species;

(b) forming one or more optical confinement layers under or around the active layer, wherein the optical confinement layers tailor a structure of guided modes within the LED; and

(c) forming one or more diffraction gratings on the optical confinement layers, wherein the diffraction gratings are two-dimensional photonic crystals that extract light from the LED.

18. The method of claim 17, further comprising forming a buffer layer on the substrate, wherein the active layer is formed on the buffer layer.

19. The method of claim 17, wherein the diffraction gratings direct emissions outside the LED and convert guided modes into extracted light.

20. The method of claim 17, further comprising depositing one or more layers on one or both sides of the LED, wherein the layers function as a mirror, electrical contact and/or diffraction grating

21. The method of claim 17, where the optical confinement layers enhance light extraction by the photonic crystals.

22. The method of claim 21, wherein the optical confinement layers help to excite those modes localized above the optical confinement layers.

23. The method of claim 17, wherein light is primarily emitted into modes that interact with the photonic crystals, so that guided modes that are usually lost are diffracted outside the LED.

24. The method of claim 17, wherein the photonic crystals cross the light emitting species in the active layer.

25. The method of claim 17, wherein the photonic crystals are situated within one or a few optical lengths from the light emitting species in the active layer.

26. The method of claim 17, wherein the LED retains a planar single layer structure.

27. The method of claim 17, wherein the photonic crystals include a taper comprised of variable hole lines.

28. The method of claim 27, wherein the taper comprises one or more periods of modified holes, and the modified holes have a variable hole depth, variable hole period, or variable hole diameter.

29. The method of claim 17, wherein characteristics of the photonic crystals are varied along its structure, so as to modify properties of the photonic crystals.

30. The method of claim 17, wherein a light generation region coincides or overlaps with the photonic crystals, so that guided light does not suffer from reflexion or scattering at an interface to the photonic crystals region.

31. The method of claim 17, where a position of the light emitting species is finely tuned, so as to precisely control its emission properties.

32. The method of claim 17, wherein, by suitable tailoring of a guided modes structure, light diffraction by the photonic crystals occurs in a given range of directions, thereby forming a highly directional light source.

33. A device fabricated according to the method of claim 17

See full document in pdf.