Flexible OLEDs with Adjustable Colors – New Design Options for Lighting Designers

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, one of the leading R&D partners for surface technologies and organic electronics, specializes in the development and fabrication of OLED modules with unconventional properties for specific client designs. The Institute will debut flexible adjustable-color organic light-emitting diodes (OLEDs) at ISAL 2017 in Darmstadt, Germany from September 25-27, 2017 at its booth (No. 31).

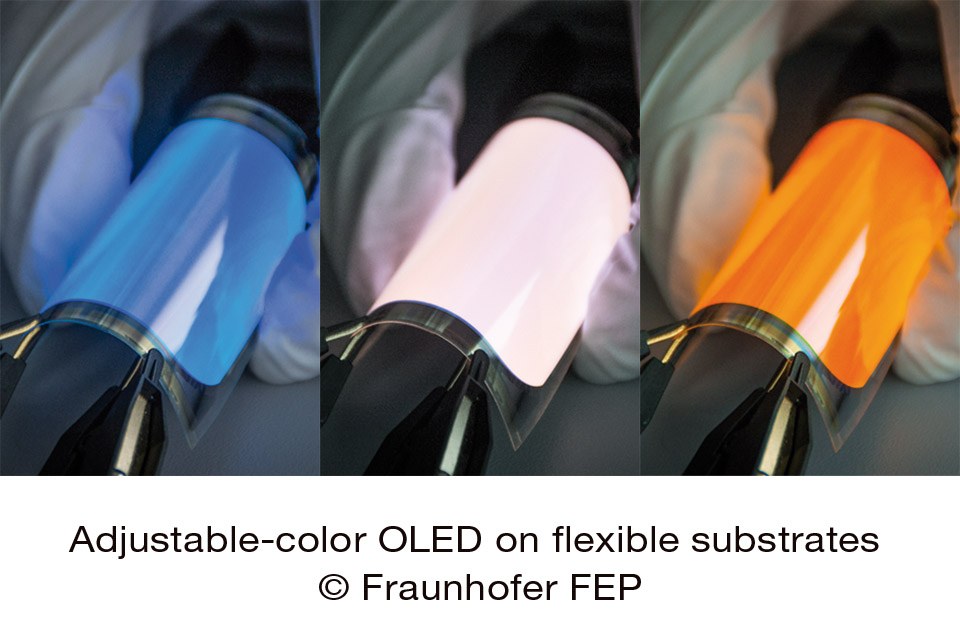

With their unique characteristics like bendabilty, segmentation, transparency, and their nearly unlimited range of shapes, organic light-emitting diodes (OLEDs) facilitate diverse new design opportunities by virtue of their being efficient areal lighting sources fabricated on flexible substrates.

In 2015, scientists of the Fraunhofer FEP were successful for the first time in processing adjustable-color OLEDs on rigid substrates. This facilitated the extension of the application spectrum of OLEDs, such as for integration into vehicle interiors where the lighting levels should be controllable as a function of the time of day. Imagine employment as ambient or accent illumination, such as for lighting in museums and exhibitions, where the adjustability of color from just a single lighting component can present the works exhibited in different colors of light.

Just two years later, the next big development goal has now been reached: the Fraunhofer FEP now offers OLED emission systems featuring an adjustable color range integrated on flexible substrates. These types of OLED modules are able to switch the emitted color between two different color temperatures. In this way, a yellow-blue bi-color emission system can not only be switched between the pure emission colors of yellow and blue, but white light can also be generated through simultaneous activation of both colors.

The integration of adjustable-color OLEDs on flexible substrates brings their employment on curved surfaces in vehicle interiors such as roofs and curved fixtures into the realm of the tangible. In the meanwhile, the range of choice for substrates has also been broadened. Flexible OLEDs can be fabricated on metal and plastic films just as they can be on ultra-thin glass. The scientists will debut the new flexible variable-color OLED modules at the International Symposium on Automotive Lighting (ISAL). The symposium takes place directly after the International Motor Show Germany (IAA Pkw 2017) and addresses lighting applications in automobiles. The wide range of possibilities for OLED technology on flexible substrates for applications upon and in automobiles will be on display at the Fraunhofer FEP booth (No. 31) at ISAL.

Claudia Keibler, head of the Sheet-to-Sheet Organic Technology department at Fraunhofer FEP welcomes you: “I am looking forward to being able to personally discuss with conference visitors the astonishing opportunities of flexible OLEDs right on site. Our technological know-how and the features of our fab facility allow us not only to discuss the wishes of interested visitors, but also produce OLED samples afterwards.”

“Hands-on” Flexible OLED Lighting Workshop @ ISAL:

The “Hands-on” Flexible OLED Lighting Workshop is intended for designers and product developers from not only the automotive industry but also many other different application areas including architecture, aerospace, fashion and consumer electronics. The workshop will offer a deep level of understanding of the possibilities and technical challenges of integrating OLEDs into existing and future products, and explain how the PI-SCALE pilot line can help with this. Discussions with OLED experts from industry and R&D will offer the attendees the opportunity to work through design concepts and have their questions about the technology answered.

Three sessions of workshop will be available over the two days at the ISAL conference, and space for this workshop is limited to 40 places per session so please register your interest via the instructions as soon as possible:

http://pi-scale.eu/hands-on-flexible-oled-lighting-workshop-at-isal-2017-conference

PI-SCALE FLEXIBLE OLED DESIGN Competition 2017

Fraunhofer FEP is a key partner of the public funded project PI-SCALE (FKZ 688093) with the aim to install a European Open-Access-pilotline for the production of OLED. Within the project now the PI-SCALE FLEXIBLE OLED DESIGN COMPETITION 2017 is launched. The Competition invites designer proposals for organic light-emitting diode (OLED) lighting and signage applications. Submission is possible until September 17, 2017. The competition is open to individuals, groups and organizations from every country in the world. There is no limit on the number of entries per person. Participation is free. Further interaction with Grant Winner occurs after award of prize, as there is opportunity to fabricate the OLED design prototype with the help of technical experts.

More information: http://pi-scale.eu/923-2

About Fraunhofer FEP:

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP is located in Dresden and focuses on developing innovative solutions, technologies and processes for surface modification and organic electronics.

Our core technologies are electron beam technology, sputtering technology, plasma-activated high-rate deposition, high-rate PECVD, and technologies for organic electronics and IC-/System design, which we use to develop solutions for various industrial tasks in surface treatment, vacuum coating and for organic semiconductors.

We offer a broad range of research, development and pilot manufacturing opportunities, especially for the treatment, structuring and finishing of surfaces as well as for OLED microdisplays, organic and inorganic sensors, optical filters and flexible OLED lighting. Our fields of work are subdivided into 7 business units based on the different materials and geometries being processed and due to special technological synergies.

The deposition of single layers and multilayer systems as well as the processing of surfaces are of huge practical importance across all industries. In addition, the development and integration of flexible organic electronics, OLED devices and OLED-on-silicon technologies offers a wide range of advantages and possibilities for novel applications such as wearables, data glasses, flexible lighting or microdisplays with sensor functions in environmental or medical solutions.

Whether in mechanical engineering, for use of solar energy in the field of smart building and architecture, in packaging industry, biomedical engineering, agriculture, preservation or in optics, sensor technology and electronics sector: We develop suitable processes and technologies as well as appropriate prototypes, devices and technological key components for our industrial customers as well as partners from research, scientific or public sectors from all over the world.

Feasibility studies, to evaluate surface coating or the integration of organic electronics in devices and pilot production, to facilitate the introduction of new customer products to the market, are also included in our range of services. The upscaling of technologies to industrial quantities and the integration into suitable plant technology and into existing production processes as well as the possibility of technology transfer and licensing are essential services of our institute. The cost efficiency of a technology for industrial production is always taken into account.

Together with companies, research institutions and public institutions we are working on novel, pioneering technologies within public funded projects of various funding authorities. By this we are continuously enhancing our comprehensive know how, which sets the basis to support our customers with their research and development projects from the first concept phase up to industrial realization.