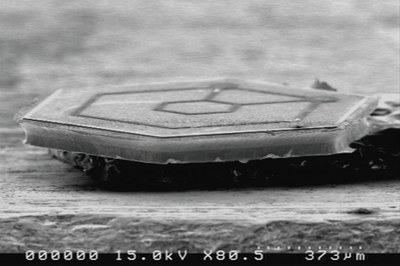

Honeycomb™ LED Chip from Verticle Inc.

Verticle, Inc (www.verticleinc.com) of Dublin, California has announced the world's first hexagonal LED chip. Honeycomb™ LED Chip, named after its hexagonal shape, is a vertically structured LED chip developed especially for high power LED applications. It is expected to bring a higher chip count per wafer and better optical power over conventional square or rectangular type LEDs, said Dr. Mike (M.C.) Yoo, Company CEO.

A hexagonal LED chip yields multiple benefits around cost, efficiency, and beam profile. The first advantage of Honeycomb™ is a higher chip count from the wafer since hexagon is the most closely-packed structure inside of a circular wafer. A wafer can yield 15% more haxagonal chips than square or rectangular chips of equivalent size. Second, hexagonal chip aids in the current spreading, with the resulting higher light output than conventional chips. Last but not least of the hexagonal chip's advantage is the light output enhancement after packaging. Honeycomb™ chip produces a beam profile which is much closer to the circular shape of circular lens used in optic design. In contrast, the beam profile of the typical square or rectangular chip, when combined with circular lens, is normally distorted.

Although hexagonal chip's distinctive advantages over conventional chips are widely known, it has not been realized in production up to now. The main reason is the difficulty in chip separation with conventional scribing or dicing. However, chemical chip separation technique invented by Verticle Inc. makes the chip separation step much easier and quicker than conventional chip separation techniques. Verticle's chemical chip separation is a highly innovative chip singulation technique that can chemically etch the street line, to easily produce chips of any shape. Moreover, with this technique, Verticle can handle multiple wafers in one batch, resulting in chip separation throughputs which are 500 times greater than with conventional chip separation methods.

Verticle, Inc is an LED chip company located in the Silicon Valley, with production facilities in Korea. Verticle specializes in manufacturing vertical type LED chips for BLU and LED lighting using a patented Cu substrate and Chemical Chip Separation Technology.

For more information, contact info@verticleinc.com or jkang@verticle.co.kr