InteGreat Project Successfully Researched New Approaches to LED Production

In the InteGreat research project, Osram Opto Semiconductors coordinated a consortium comprising seven partners from science and industry. Between December 2014 and February 2018 the project partners investigated time-honored manufacturing approaches and know-how along the entire LED production process with the aim of identifying potential areas for optimization. The new insights allow for LED products to be given additional superior properties that would have been difficult or even impossible to achieve with the technologies previously used to produce LEDs.

Osram Opto Semiconductors, Osram, the Fraunhofer Institute for Integrated Systems and Device Technology (IISB), the Fraunhofer Institute for Reliability and Microintegration (IZM), Würth Elektronik, LayTec AG and Mühlbauer GmbH & Co KG investigated new approaches for manufacturing very small surface emitting LED chips and packaging technologies, among other things, as part of the “Photonic Process Chains” initiative.

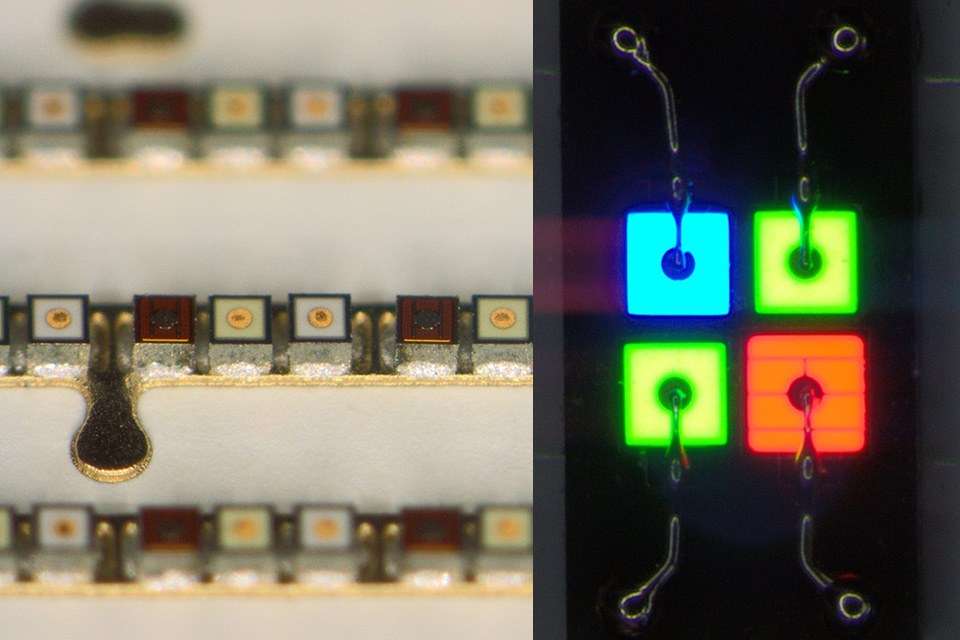

At the heart of the project was wafer level packaging as well as investigations into planar contacts. One of the pioneering approaches to emerge from the project is planar interconnect technology in which the bond wire is replaced by a thin flat metal connection. This moves the surface emitter to the surface of the package. The light can therefore be used more directly, unlike with conventional components. This leads to smaller losses in efficiency and luminance and consequently to greater brilliance and cost savings in operation. Other new technologies along the entire value-added chain for functional full-color video wall modules with a pixel pitch of 1 mm were successfully demonstrated.

The results of the project can be applied not only to large-format video walls but also to new applications such as in ambient lighting and sensor systems. Thanks to the modular structure of the project comprising four work packages, many results can now be quickly transferred to product development and production. The integration of LEDs in industrial applications and also in areas such as the mobility of the future can therefore be accelerated. The results also open up huge potential in infotainment.

“The results of the InteGreat research project represent a major advance for the future of LEDs. Our powerful consortium of partners from science and industry has delivered extraordinary achievements in three years. Once again we have been able to demonstrate the powers of innovation in Germany as a center of scientific know-how”, said Frank Singer, Predevelopment Group Leader at Osram Opto Semiconductors.

Acknowledgements:

Innovative technologies and pioneering findings for LED manufacturing as a result of the project funded by the German Federal Ministry of Education and Research (BMBF)

About Osram:

Osram, based in Munich, is a leading global high-tech company with a history dating back more than 110 years. Primarily focused on semiconductor-based technologies, our products are used in highly diverse applications ranging from virtual reality to autonomous driving and from smartphones to smart and connected lighting solutions in buildings and cities. Osram uses the endless possibilities of light to improve the quality of life for individuals and communities. Osram’s innovations enable people all over the world not only to see better, but also to communicate, travel, work and live better. Osram has approximately 26,400 employees worldwide as of end of fiscal 2017 (September 30) and generated revenue of more than €4.1 billion. The company is listed on the stock exchanges in Frankfurt and Munich (ISIN: DE000LED4000; WKN: LED 400; trading symbol: OSR). Further information can be found at www.osram.com