LED System Design with Cititzen LEDs (by A. Lohrer, Endrich)

Rapid improvements in high-power LEDs are opening up more and more application possibilities. These go beyond the simple replacement of the light bulb: thanks to fast technology advancements creative lighting solutions such as object illumination that were unthinkable a few years ago are now possible (see Figure - Illuminated Bridge). Recent price trends have resulted in many large lighting companies now exclusively using LEDs as light sources for new developments.

While lm/W efficacy used to be the only requirement in the past, now properties such as durability, colour stability, colour rendering and binning are also key. LEDs provided by Citizen are outstanding in these areas. However, to operate high-power LEDs safely and durably, additional components such as power supplies and optics are needed.

Simple application requirements can be solved as follows:

Selection of light properties such as colour temperature and rendering

Before choosing a design or the actual LED, it is important to select the colour temperature and colour rendering index for an appealing lighting solution. Endrich Bauelemente offers Citizen LEDs with colour temperatures of 2700K, 3000K, 3500K, 4000K and 5000K. There are already applications on the market, where the colour temperature is adjustable by the operator. To achieve this, two LEDs with different colour temperatures and separate LED control are needed.

A homogeneous lighting solution requires LEDs with an exact light colour. For those applications, Citizen offers so-called MC Adam Step 3 binning. At 3000K, the tolerance is approximately + - 70 K, which is almost unnoticeable by the user. The light efficacy of modern LEDs is around 30-35%, the remaining energy input is converted into heat. It is therefore important for the user to know how the colour is affected by the temperature. In some competitor products the deviation can be up to 300K.

In addition to an exact light colour, the colour rendering index (CRI), often referred to as Ra, is also crucial for high quality lighting. CRI is a measure for how naturally the colours of an illuminated object are represented. Citizen currently offers LEDs with Ra typical 65 for solutions requiring high lm/W efficacy for outdoor use as well as LEDs with Ra min 80 with lower light output for interior lighting. At Light + Building 2012, the company launched the new Ra 90 series which will be available from the middle of this year. During production R9 is particularly tightly controlled. This value is a measure for the representation of red colours, which are illuminated by the LED.

LED selection

The first question at the beginning of a project is how to establish the light source. It is possible to produce the light with several LEDs on an area or a strip. The advantage of this approach is that you can produce a light effect where the light source is not directly visible. Citizen offers three completely new SMD products in the 0.06 W, 0.1 W and 0.2 W class. Since these use the latest generation of LED dice, efficacy is up to 134 lm/W (5000K). LED efficacy has also been significantly enhanced for lower colour temperatures, and LEDs with 126 lm/W at 3000K are available. All new series offer a colour rendering index of Ra> 80 and MC Adam Step 3 binning. (see Figure - CLL600N, CLL050N)

Alternatively, a lighting solution can use one or more high-performance LED as light source. The Citizen product portfolio includes LEDs ranging from 2.7 W to 82.4 W in 5 different sizes.

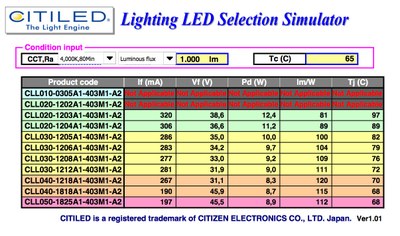

To help with component selection Endrich offers a handy lumen calculator on its homepage at http://www.endrich.com/box/CITILED_SelectionSimulator_101.xls.

After entering the desired colour temperature and brightness a list of suitable LEDs for the given requirements is displayed. The best solution is not always the LED with the lowest power. Since efficacy increases with LED size, the more costly LED is compensated by using a smaller heat sink.

Power supply selection

With a high-power LED, the current depends exponentially on the voltage – in other words, a small voltage change can cause a large change in current. Temperature changes at a constant voltage also influence the current, while current changes affect colour temperature and brightness. A stable system therefore requires serial wiring and a current-controlled LED ballast, which constantly readjusts the set current. The required current value can be obtained by entering the desired brightness into the lumen calculator.

Of course, standard solutions do not always cover the required currents. For those cases, NMB Minebea from Endrich provides programmable drivers that can be set in 5mA steps via USB interface. The latest generation Citizen LEDs are not tied to a fixed current value. These ballasts therefore allow the realization of a wide range of application solutions.

It is interesting to note that power supply manufacturers are increasingly adapting to the needs of LED lighting. In the past, many manufacturers only provided devices with a maximum secondary power supply of 48 V. Multi-chip solutions of several LED vendors such as Citizen need up to 60 V in order to ensure an adequate operation. Endrich now offers complete systems with a driver and a LED that achieve up to 16500 lm. This raises the legitimate question whether it is possible to sufficiently cool a power of 160 W. For the >60 W performance class, Endrich is working very closely with manufacturer Inventronics who provides constant current sources of up to 200 W. These devices are available in IP67 and therefore suitable for outdoor use.

Efficacy is a key factor for the power supply. While individual components, such as the LED, the ballast and the optics are crucial for optimum overall system efficiency, it is even more important to consider how the LED supplier handles heat dissipation. At 150 W with 85% efficiency heat loss amounts to 26.5 W. At 95% efficacy the heat to be dissipated is only 7.9 W.

Most ballasts are subject to power derating when temperatures reach above 50°C. The wrong selection of power supply can therefore very quickly lead to overload or a severe shortening of product life.

Heat dissipation in the ballast is therefore an essential prerequisite for long product life and an important quality factor. A comparison of a 150W competitor product, for example, has shown a housing temperature of 51°C. For the same power, the Inventronics power supply measured a housing temperature of only 41°C. The required life expectancy of >50,000 h can only be achieved if the used component parts operate below their maximum permissible temperature range.

With Lumotech, Inventronics and NMB Minebea, Endrich offers suitable LED ballasts for all requirements. (see Figure - LED Power Supplies)

Mechanical connection/cooling

These days support systems for multi-chip LEDs are available. The holders provide a simple electrical contact and mechanical attachment to the LED. However, to guarantee long LED life, sufficient cooling is important. Two points are crucial in this context: First, a good thermal connection to the heat sink is required. This can, for example, be achieved with a thermal conductive foil. Second, a sufficient heat sink is required for heat dissipation.

A simple check as to whether cooling is sufficient is to measure the LED temperature Tc in the settled state. Each high-power LED must be adequately tested in each application to ensure that there is sufficient cooling and that the LED is operated below the allowed maximum Tjunction (Tj). The product of thermal LED resistance Rj and power dissipation Pd have to be added to the measured LED temperature Tc: Tj = Tc + Rj * Pd.

As long as the junction temperature Tj remains below the specified value, the required LED life can be guaranteed. If the calculated value is greater than Tj, further cooling measures are necessary or the thermal connection of the LED to the heat sink needs to be improved.

In cooperation with partner Turck Duotec, Endrich Bauelemente has developed a high-power module in which a LED with a very low thermal resistance is mounted in a mechanically reproducible way on to a copper plate. The copper plate dissipates the heat and can be connected directly to a customer application via four bolts. The power supply is easily connected via a LED poke-in connector.

This module forms the basis for a lot of requests for customer-specific products in the integration of high-performance high-power LEDs.

(see Figure - Truck LED Module)