Organic Electronics - How To Make Contact Between Carbon Compounds and Metals

Organic electronics has already hit the market in smartphone displays and holds great promise for future applications like flexible electroluminescent foils (a potential replacement for conventional light bulbs) or solar cells that convert sunlight to electricity. A reoccurring problem in this technology is to establish good electrical contact between the active organic layer and metal electrodes. Organic molecules are frequently used also for this purpose. Until now, however, it was practically impossible to accurately predict which molecules performed well on the job. They basically had to be identified by trial-and-error. Now, an international team of scientists around Dr. Georg Heimel and Prof. Norbert Koch from the HZB and the Humboldt University Berlin has unraveled the mystery of what these molecules have in common. Their discovery enables more focused improvements to contact layers between metal electrodes and active materials in organic electronic devices.

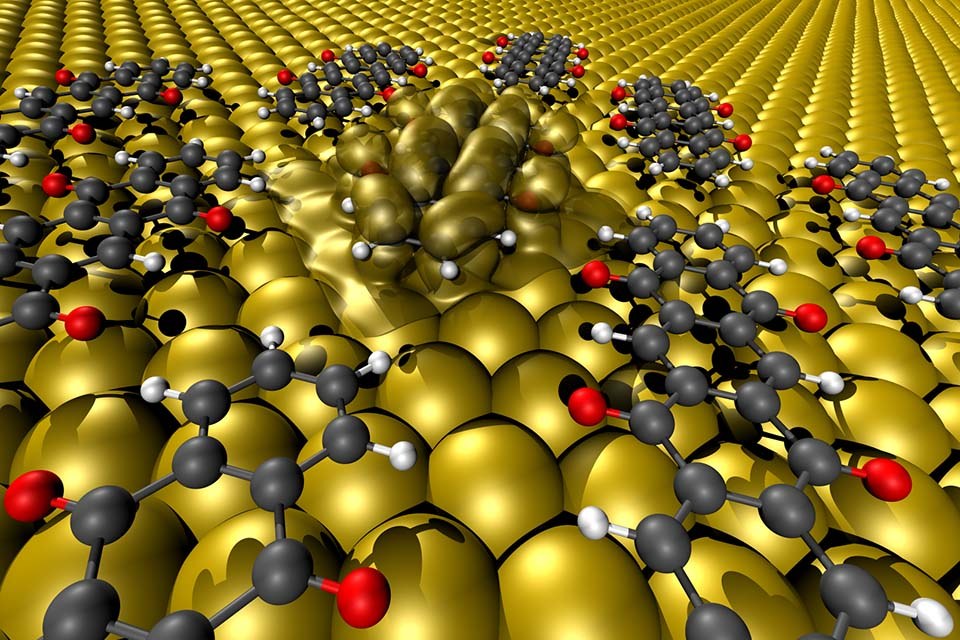

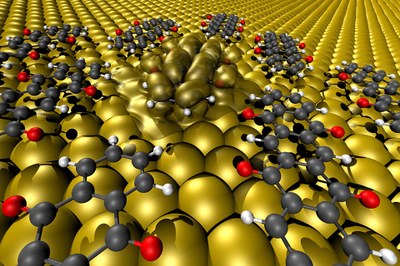

"We have been working on this question for a number of years now and could at last come up with a conclusive picture using a combination of several experimental methods and theoretical calculations," Georg Heimel explains. The researchers systematically examined different types of molecules whose backbones consist of the same chain of fused aromatic carbon rings. They differed in just one little detail: the number of oxygen atoms projecting from the backbone. These modified molecules were placed on the typical contact metals gold, silver, and copper.

Using photoelectron spectroscopy (UPS and XPS) at HZB's own BESSY II synchrotron radiation source, the researchers were able to identify chemical bonds that formed between the metal surfaces and the molecules as well as to measure the energy levels of the conduction electrons. Colleagues from Germany's Tübingen University determined the exact distance between the molecules and the metal surfaces using x-ray standing wave measurements taken at the ESRF synchrotron radiation source in Grenoble, France.

These experiments showed that, upon contact between the oxygen atoms protruding from the backbone and several of the metals, the molecules' internal structure changed in such a way that they lost their semiconducting properties and instead adopted the metallic properties of the surface. Despite similar prerequisites, this effect was not observed for the "bare"-backbone molecule. From the observation which molecules underwent these kinds of drastic changes on what metal, the researchers could derive general guidelines. "At this point, we have a pretty good sense of how molecules ought to look like and what their properties should be if they are to be good mediators between active organic materials and metal contacts, or, as we like to call it, good at forming soft metallic contacts," says Heimel.

Experts from a number of other German universities and from research facilities in Suzhou (China), Iwate and Chiba (Japan), and ESRF (France) have also contributed substantially to this publication.

About Helmholtz-Zentrum Berlin:

The Helmholtz-Zentrum Berlin für Materialien und Energie (HZB) operates and develops large scale facilities for research with photons (synchrotron beams) and neutrons. The experimental facilities, some of which are unique, are used annually by more than 2,500 guest researchers from universities and other research organisations worldwide. Above all, HZB is known for the unique sample environments that can be created (high magnetic fields, low temperatures). HZB conducts materials research on themes that especially benefit from and are suited to large scale facilities. Research topics include magnetic materials and functional materials. In the research focus area of solar energy, the development of thin film solar cells is a priority, whilst chemical fuels from sunlight are also a vital research theme. HZB has approx.1,100 employees of whom some 800 work on the Lise-Meitner Campus in Wannsee and 300 on the Wilhelm-Conrad-Röntgen Campus in Adlershof.