Fischer Elektronik Presents New Phase Change Thermal Conductive Material

Company Fischer Elektronik GmbH & Co. KG extends their extensive product portfolio of thermal contact materials by new phase change thermal conductive materials which provide an alternative to the conventional thermal conductive pastes. The new material types combine the advantages of high thermal performance together with the reliability of phase change materials and with a simple application on the surfaces to be contacted.

The thermal conductive material with the designation FSF 15 P and FSF 20 P is solid in its delivered condition and begins to flow at a phase change temperature between 52°C and 48°C each. Hereby microscopic small unevennesses between heat source and a heat sink for example will be compensated.

During the moistening air escapes out of the area of the boundary layer, which leads to a significant reduction of the thermal impedance and simultaneously to an optimal heat transfer resistance. The material thicknesses vary from 0,114 mm up to 0,2 mm whereby the customers can select the particular material thickness contact surfaces depending on the unevenness and roughness.

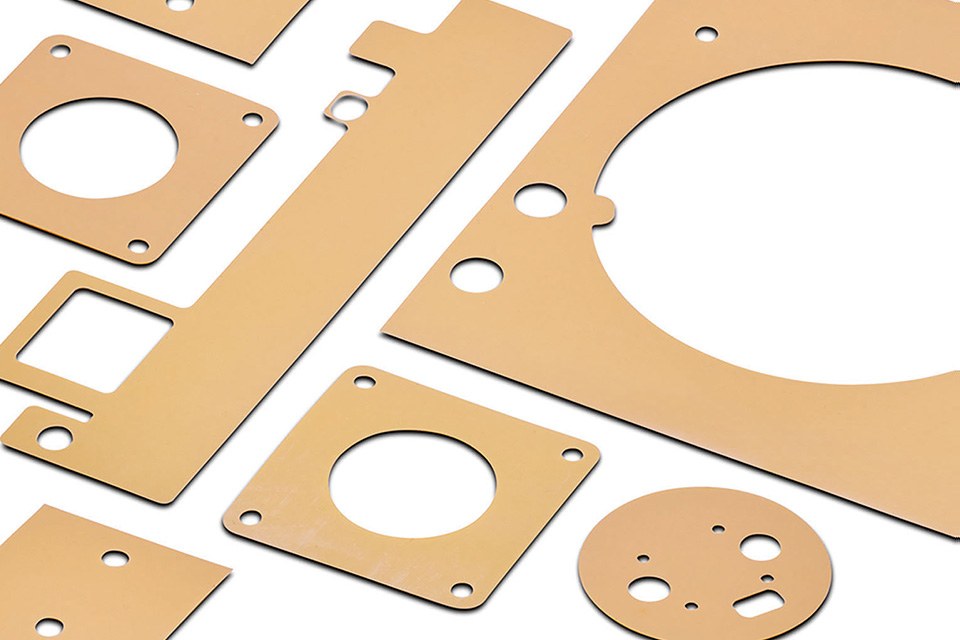

The thermal conductivity of the new designs is within the scope of 1,5 up to 2 W/mK. For a simple handling (easier installation) in the application both types have a one-sided natural adhesive layer. The basic material of the article FSF 15 P is available as sheet or roll material whereas the FSF 20 P is only available as sheet material in the dimension 300x400 mm. Special cuts and contours of the phase change materials will be performed according to customized drawing specifications by means of latest processing machines.

The product specialists at Fischer Elektronik http://www.fischerelektronik.de/en/ will be happy to assist you with any queries you may have or any additional information you require.

About Fischer Elektronik:

Fischer Elektronik is a leading producer of thermal management solutions for the whole electronic industry. High Power LED applications are our latest field of activities with all our almost 40 years of experience in the background. On the edge of this new technology, we can give support right from the start with the knowledge of our application engineers and as well as with our sophisticated 3D simulation and drawing programmes. Our core capabilities: - all articles in standard or customs design versions available - own surface treatment facilities - wide standard programme (more than 700 profiles) of extruded heatsinks - machining according to customers request - heatsinks for LED, cooling aggregates and thermally conductive foils. We also have a large selection of connectors for PC boards that is complemented by a diverse range of casings with functional designs. In addition to standard catalogue items, we also provide customer-specific solutions in all areas.