SinkPAD Corporation Will Introduce Their New Cool Down Aluminum PCB Applications at the LEDshow in Las Vegas

SinkPAD Corporation’s Vice President of Marketing and Business development Sam Bhayani has announced that his company SinkPAD Corporation will be exhibiting at the LED show in Las Vegas on July 27th. The LED show and conference is on July 26th and 27th, the conference is both days while the expo is on the 27th. The LED show attracts an exclusive group of buyers from every subset of the LED lighting industry. It has a more direct approach to marketing and promoting LED products. The show is designed to encourage manufacturers and their customers to come face to face discussing their LED lighting needs and solutions. The expo is 20,000 feet of interaction between the right companies.

Commenting on the LED show Mr. Bhayani said, “This is our first show since developing our new SinkPAD* thermal-management Printed Circuit Board technology and we chose it for a reason. We felt that this was the very best venue for us to introduce this new and important technology. We want to show those LED companies at the show that we have the right solution to solve their high-power, high-bright LED challenges. We are very excited about being at the LED show in Las Vegas; we feel that it provides us with the opportunity to be in the right place at the right time.”

SinkPAD corporation’s new thermal technology printed circuit boards are a complete and effective solution to the challenges faced by the solid state lighting industry, specifically those with aluminum LED PCB applications.

Available now, the new SinkPADTM technology significantly improves LED thermal management in all LED systems. It is most effective in high-power high-bright surface mount LED systems; those systems that cannot efficiently dissipate heat thus making them unviable for commercial systems.

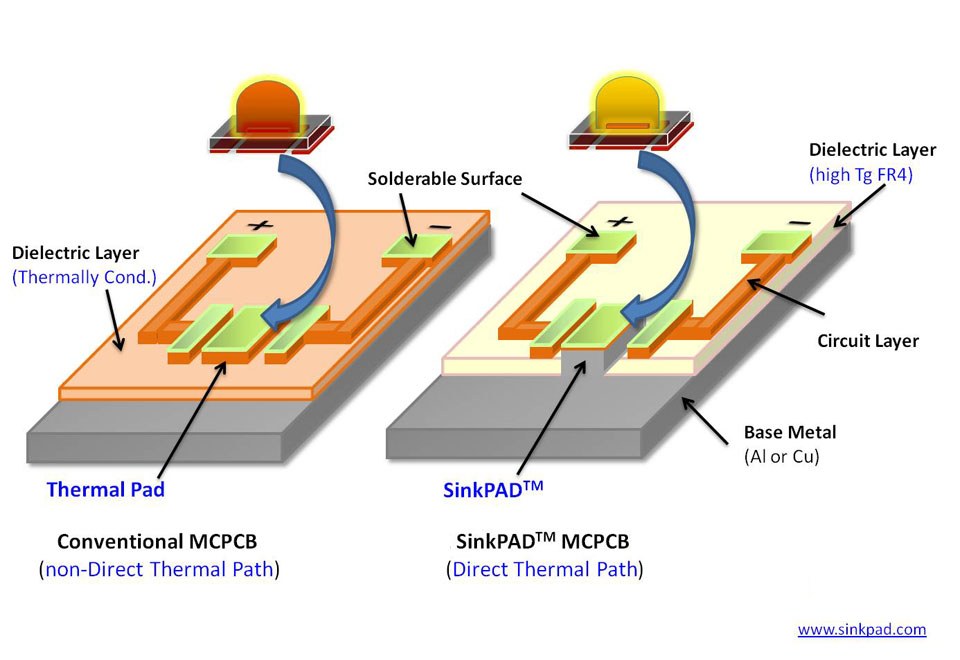

SinkPADTM conducts heat out of the LED system (LED cooling) by enabling a direct thermal path between the LED and surrounding atmosphere, which eliminates thermal resistance introduced by the dielectric material in a traditional IMS PCB or MCPCB. The SinkPADTM design completely removes the substance with the lowest thermal conductivity/highest thermal resistance from the structure. SinkPADTM still uses a dielectric, but this dielectric isolates the metal base electrically and leaves it thermally connected. The thermal path should be electrically neutral within the LED package, i.e. Cree XLamp, Luxeon Rebel from Philips Lumiled, PhlatLight from Luminus, in order to solder the LED directly to the SinkPADTM. To find out how SinkPAD’s technology can remove the heat in your LED application, contact SinkPADTM Corporation or visit the SinkPAD website, www.sinkpad.com.

About SinkPAD:

SinkPAD Corporation is an innovative thermal management company addressing the thermal challenges facing the electronics industry. The company’s patent pending PCB technology makes it possible to conduct heat out of the LED system and into the atmosphere quickly and cost effectively while providing their customers with a first-to-market competitive advantage.