TE Connectivity Introduces LUMAWISE Endurance N Base with Vent

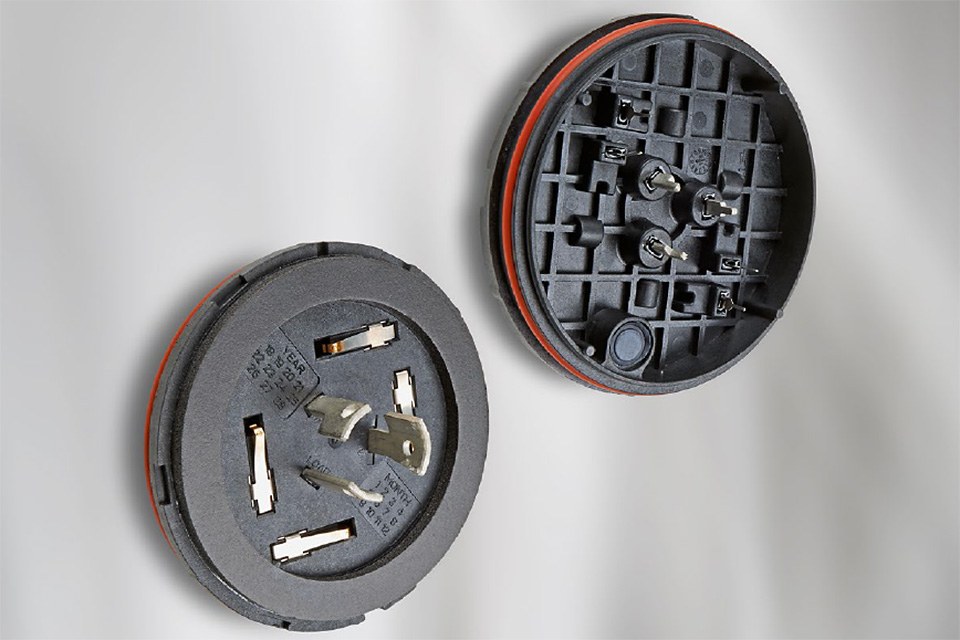

TE Connectivity’s (TE) LUMAWISE Endurance N base with vent is ANSI 136.41 compliant for photocontrols and accepts sleeves and covers in varying heights. These components are assembled to provide a total power and signal interface between the photocontrol module and a lighting fixture’s mating receptacle.

Benefits:

• Ensures long term reliability using a well engineered power and signal interface between photocontrol and dimming receptacle

• Protects from dust and water ingress using an IP66 rated control enclosure

• Incorporating a vent into the base assemblies enables full life expectancy of the electronics inside the enclosure

Applications:

• Roadway and street lighting

• Parking lots

• Pathway and trails

• Parks

Electrical:

• Power Contacts: 15 A, 480 VAC

• Signal Contacts: 1.5 A, 30 VDC

Mechanical:

• Operating Temperature Range: -40°C to 10°C

Materials:

• Contact Plating: Tin plated power contacts and gold plated signal contacts

• Housing Material: 94 V0

• Color: Black

The LUMAWISE Endurance N controller interface is used in applications such as LED outdoor roadway, street and area lighting fixtures. The base assembly solution includes power twist lock terminals, spring leaf signal contacts and a separately packaged foam gasket. When coupled with the 5-VA rated cover or in combination with optional side or topside aperture sleeves, the fully assembled photocontrol achieves an IP66 seal rating.

The LUMAWISE Endurance N control base assemblies are offered with an integral vent. The vent provides rapid pressure equalization inside the sealed photocontrol and minimizes condensation through vapor diffusion. The vent also prevents the entry of contaminants including dust, dirt and debris that can negatively impact the performance, long term reliability and life expectancy of the sensitive electronics within the enclosure.

About TE Connectivity:

TE Connectivity Ltd. is a $13 billion global technology and manufacturing leader creating a safer, sustainable, productive, and connected future. For more than 75 years, our connectivity and sensor solutions, proven in the harshest environments, have enabled advancements in transportation, industrial applications, medical technology, energy, data communications, and the home. With 78,000 employees, including more than 7,000 engineers, working alongside customers in nearly 150 countries, TE ensures that "Every Connection Counts".

Learn more at www.te.com